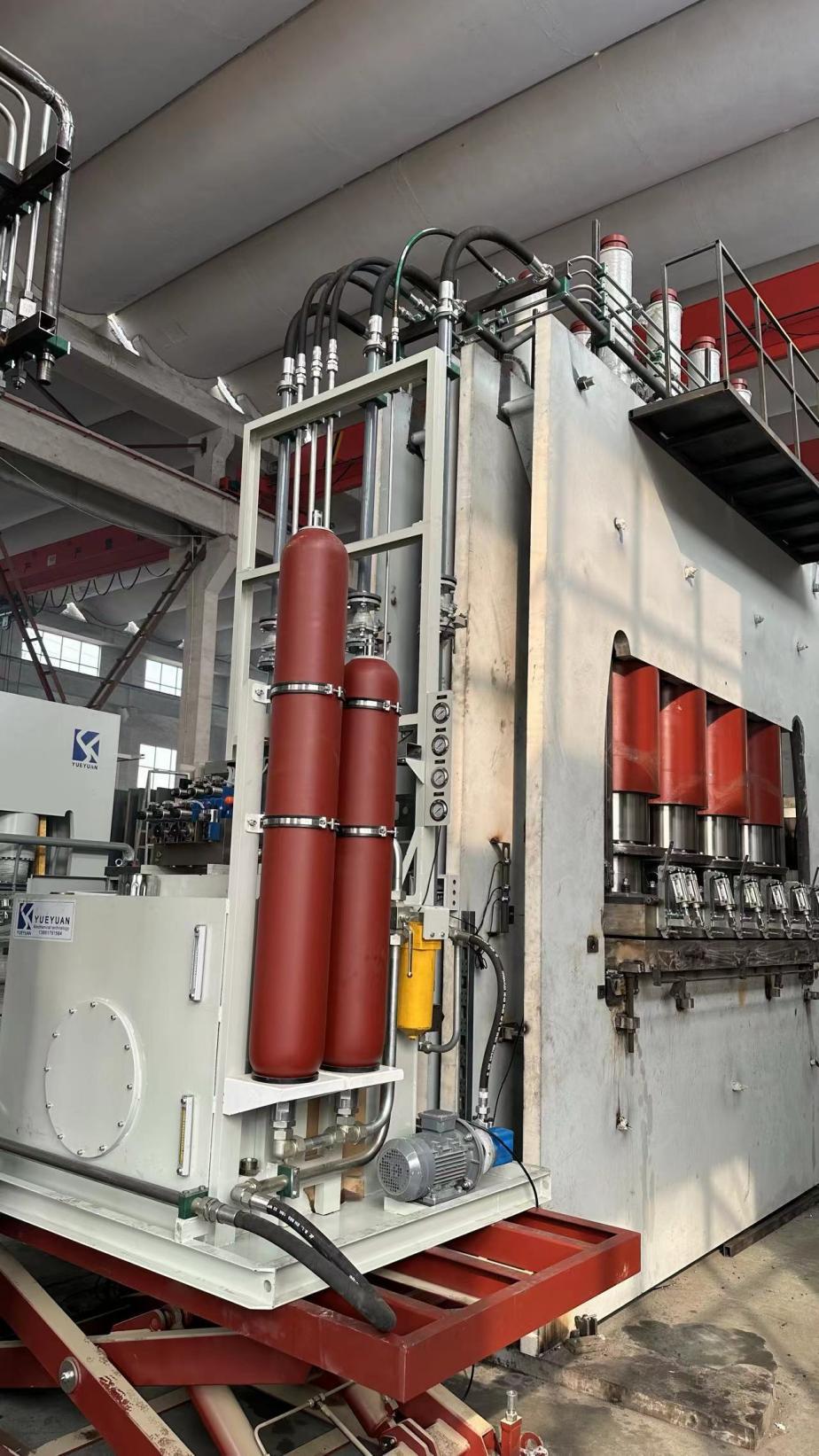

Cold press machine safety operation and maintenance specifications

Published Time:

2022-01-24

Objective: To analyze the hazards of cold press machines during operation, standardize safe operating procedures and precautions, and prevent accidents.

Objective: Analyze the hazards of cold press machines during operation, standardize safe operating procedures and precautions, and prevent accidents.

Scope of application: This regulation applies to safe operation during the actual operation of cold press machines.

I. Hazard Factors

(1) Negligence Operation Hazard Factors

1. Failure to learn the safe operation knowledge of cold press machines as required, and failure to receive qualified pre-job training.

2. Failure to operate and use strictly in accordance with the instructions and safety operating procedures.

(2) Mechanical Hazard Factors

1. Operators put their hands or other body parts into the danger zone during operation.

2. Violation of the warnings, cautions, and signs prohibiting operations in the machine manual.

3. Failure to carefully inspect the equipment as required before use.

4. Failure to hang warning signs during maintenance.

(3) Electrical Hazard Factors

1. Unauthorized modification and disassembly of machinery.

2. Failure to operate correctly according to the instructions and safety regulations.

3. Operators violate electrical safety regulations during operation, opening the electrical box while powered on.

4. Equipment maintenance personnel lack professional electrical safety knowledge or do not follow electrical safety regulations and electrician operating procedures, easily causing electric shock accidents during maintenance.

(4) Noise and Dust Hazard Factors

1. Operators do not use personal protective equipment correctly as required.

2. Fire prevention measures do not meet the requirements.

II. Safe Operating Procedures

(1) Safety Regulations

1. This machine must be operated by a designated person. Operators must receive training as required, understand the structure, performance, and use of the machine, and master the safety technology knowledge related to use and maintenance. They can only operate after passing the post-training assessment.

2. Operators must strictly abide by the safe operating procedures of the cold press machine and use it according to the machine manual and relevant safety operating regulations.

3. Operators should wear appropriate clothing and are not allowed to wear slippers; maintain a good mental state.

(2) Safe Operation

1. Remove unnecessary items from the table before operation.

2. Before operation, cut off the power switch to prevent accidents.

3. According to the machine's rated pressure, it must not exceed 5 tons to avoid damage to the motor and various components.

4. The size of the pressure plate should meet the requirements, not too wide, the length should not exceed 2.44 meters, and the width should not exceed 1.22 meters.

5. The height of the pressure plate should not exceed 100CM.

6. The control box contains high-voltage electrical appliances, and non-technical personnel are not allowed to open and repair it themselves.

7. During operation, the height of the left and right screws must be consistent.

8. After the work is completed, cut off the power, lock the switch box door, and check that everything is normal at the workstation before leaving.

(3) Electrical Safety Operation

1. Check that there is no sawdust accumulation in the electrical distribution box, the electrical grounding is good, and the electrical box door is securely closed.

2. Check that the wiring of the motor and power control switch is not damaged, and there is no sawdust accumulation on the outer casing of the electrical components.

3. Circuit faults must be eliminated by a professionally qualified electrician.

4. Electrical equipment must be sensitive and reliable, and makeshift use is strictly prohibited.

4. Electrical switches should be turned on as needed and turned off immediately when not in use. In case of power failure during work, turn off all switches, and turn on the power and switches after the power is restored.

(4) Noise and Dust Protection

1. Personnel must use personal protective equipment correctly as required.

2. Fire or explosion prevention:

(1) Check before starting the machine whether there is dust and sawdust accumulation on the electrical box and various line components.

(2) Check the equipment before operation. If any abnormality is found, operation is strictly prohibited. Report to the superior and have it repaired by qualified repair personnel before starting work.

(3) No smoking or fire is allowed in the operating area, and fire-fighting equipment must be readily available.

III. Prohibited Matters

1. When using, strictly abide by the operating requirements, and strictly prohibit violations.

2. It is strictly forbidden for personnel who have not received training or have not passed the training to operate.

3. No smoking or fire is allowed in the operating area, and the switch should be turned off and the power should be cut off after work.

IV. Emergency Measures

1. During emergency rescue, quickly, orderly, and effectively implement on-site first aid, coordinate vehicles or call 120 to safely transfer the injured. Take effective measures to prevent the expansion of injuries.

2. Notify the company's safety officer as soon as the incident occurs to guide and organize the masses to take various measures for rescue.

3. Relevant leaders quickly control the situation and conduct detection and monitoring of the hazards caused by the accident, determining the source, nature, and severity of the accident hazards.

4. In the event of a special accident, reasonable measures should be taken for rescue; if difficulties are encountered, call 119 for assistance.

5. When rescuing the injured, if it is necessary to move certain objects at the scene, the scene must be marked.

6. After the accident, based on the principle of "four nos": "the cause of the accident is not investigated and not let go; the person responsible for the accident is not dealt with and not let go; the masses are not educated and not let go; the preventive measures are not implemented and not let go", promptly investigate the cause and nature of the accident, assess the scope and severity of the accident hazards, ascertain the injuries of the personnel, conduct a thorough investigation of the cause of the accident, and summarize the experience and lessons learned from the rescue work.

V. Maintenance Regulations

(1) Maintenance Cycle: Daily maintenance, once a day (by the operator); secondary maintenance, at least once a month.

(2) Maintenance Content:

1. Daily Maintenance

1) Daily maintenance, once a day.

2) The operator cleans the workbench with compressed air.

2. Secondary Maintenance

1) Secondary maintenance, at least once a month.

2) The maintenance personnel lubricate the lifting gear box once a month.

6) The maintenance personnel check the upper and lower limit switches.

7) The maintenance personnel lubricate the lifting guide rails once a month.

8) The maintenance personnel check whether the belt tension is appropriate.