How should the furniture industry choose veneer pressing machines?

Published Time:

2023-01-05

With the dwindling resources of wood, especially precious wood, veneer is increasingly used in furniture. Veneer presses are important equipment in the pressing process and are frequently used in furniture manufacturing to press and consolidate parts. Their production capacity and technical performance constrain the production scale and product quality of enterprises. To better understand and select veneer presses, this article introduces veneer presses commonly used in the furniture industry as an example.

With the dwindling resources of wood, especially precious wood, veneer is increasingly used in furniture. Veneer presses are crucial equipment in the pressing process, frequently used in furniture manufacturing to press and consolidate parts. Their production capacity and technical performance constrain a company's production scale and product quality. To better understand and select veneer presses, this article uses the veneer press commonly used in the furniture industry as an example.

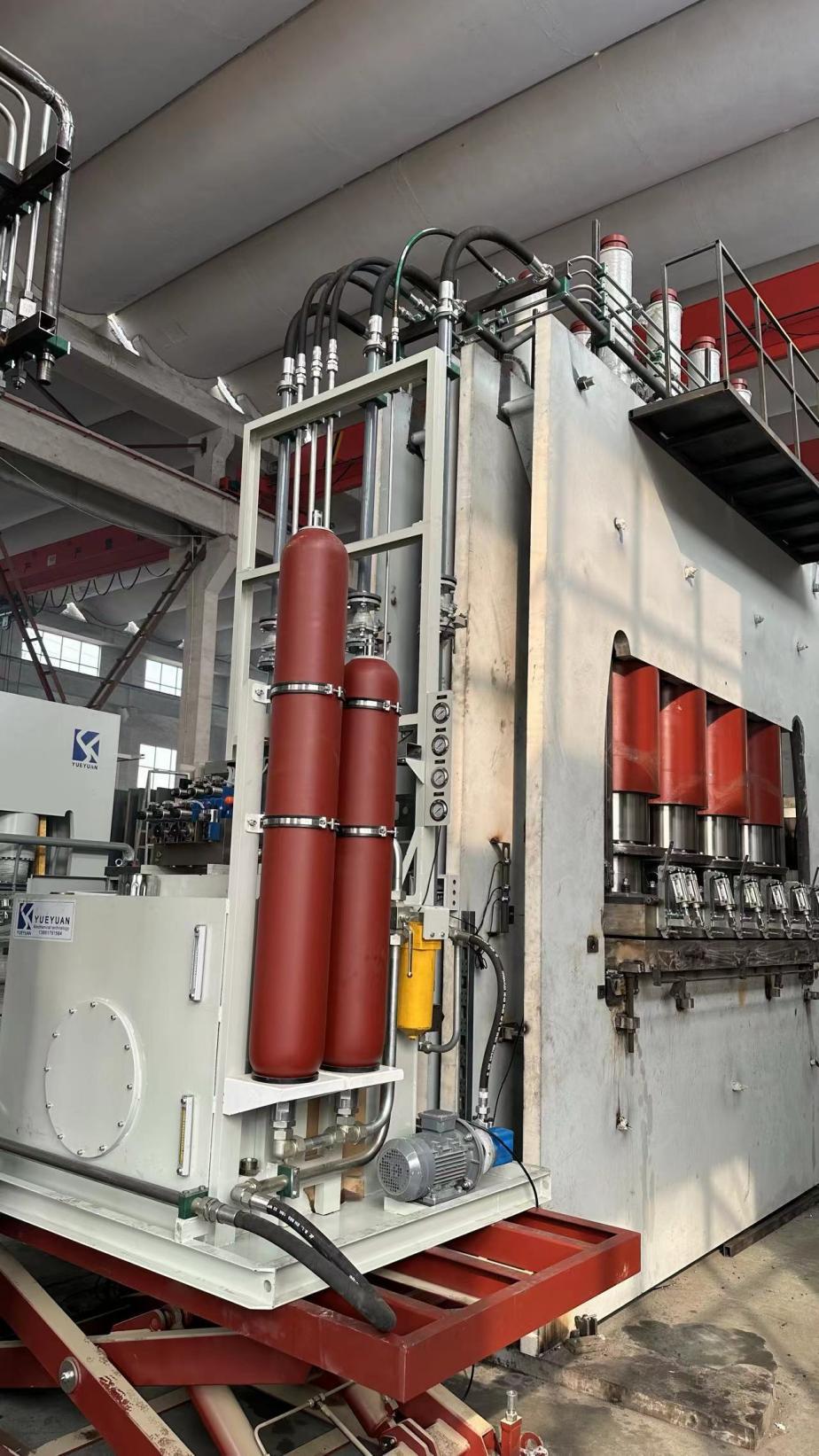

Veneer presses used in the furniture industry generally accommodate the dimensions of artificial boards (1220×2440mm). The panel pressure is typically 0.2~0.4 MPa, corresponding to a total pressure of 120t. In addition to the main technical parameters such as hot press plate size, total pressure, number of layers, and surface pressure, veneer presses also have other technical parameters such as opening and closing time, heating temperature, and productivity, which should be determined according to different process requirements. The working process of a veneer press can be divided into five stages: closing, pressurization, pressure holding, pressure release, and descent. The main body of the press can be divided into three parts: the heating system (providing the heat source), the hydraulic system (providing pressure and controlling the press's movements), and the press body (frame and control section).

Generally, veneer presses are evaluated and selected based on functionality, reliability, service, and price. This article mainly introduces veneer presses from the aspects of functionality and reliability.

1. Heating System of Veneer Press

(1) Comparison of Heating Methods

When using a veneer press, the heating method affects the temperature selection, process control, and quality of the processed products.

Traditional heating methods include steam heating and electric heating. Steam heating is fast, but requires a pressure boiler. The high pipe pressure makes steam prone to condensation, leading to uneven panel temperature. Electric heating is characterized by fast heating speed, high heating temperature, and easy control. However, its drawbacks are high power consumption, high operating costs, and difficulty in replacing resistance wires.

The advantages of heat transfer oil heating are: large heat capacity, uniform temperature, high temperature under normal pressure, low heat loss, and low production cost. The disadvantages are slow heating speed and difficult temperature control. In the furniture industry, even when the hot pressing temperature is not generally high, a hot water circulation furnace can achieve satisfactory results with low fixed investment and operating costs.

(2) Performance of Hot Plates in Veneer Presses

The performance of hot plates can be evaluated from several aspects: firstly, the materials used for the press plates; secondly, the processing precision; and finally, the arrangement of the dielectric channels in the hot press plates.