What are the operation and maintenance methods for a laminating press?

Published Time:

2023-01-11

What are the operation and maintenance methods of a veneer press? With the dwindling resources of wood, especially precious wood, more and more furniture uses pressure processing, such as veneer or sticker. Veneer press, as important equipment for pressure processing, is frequently used in furniture manufacturing for veneer and pressure molding parts

What are the operation and maintenance methods of a veneer press?

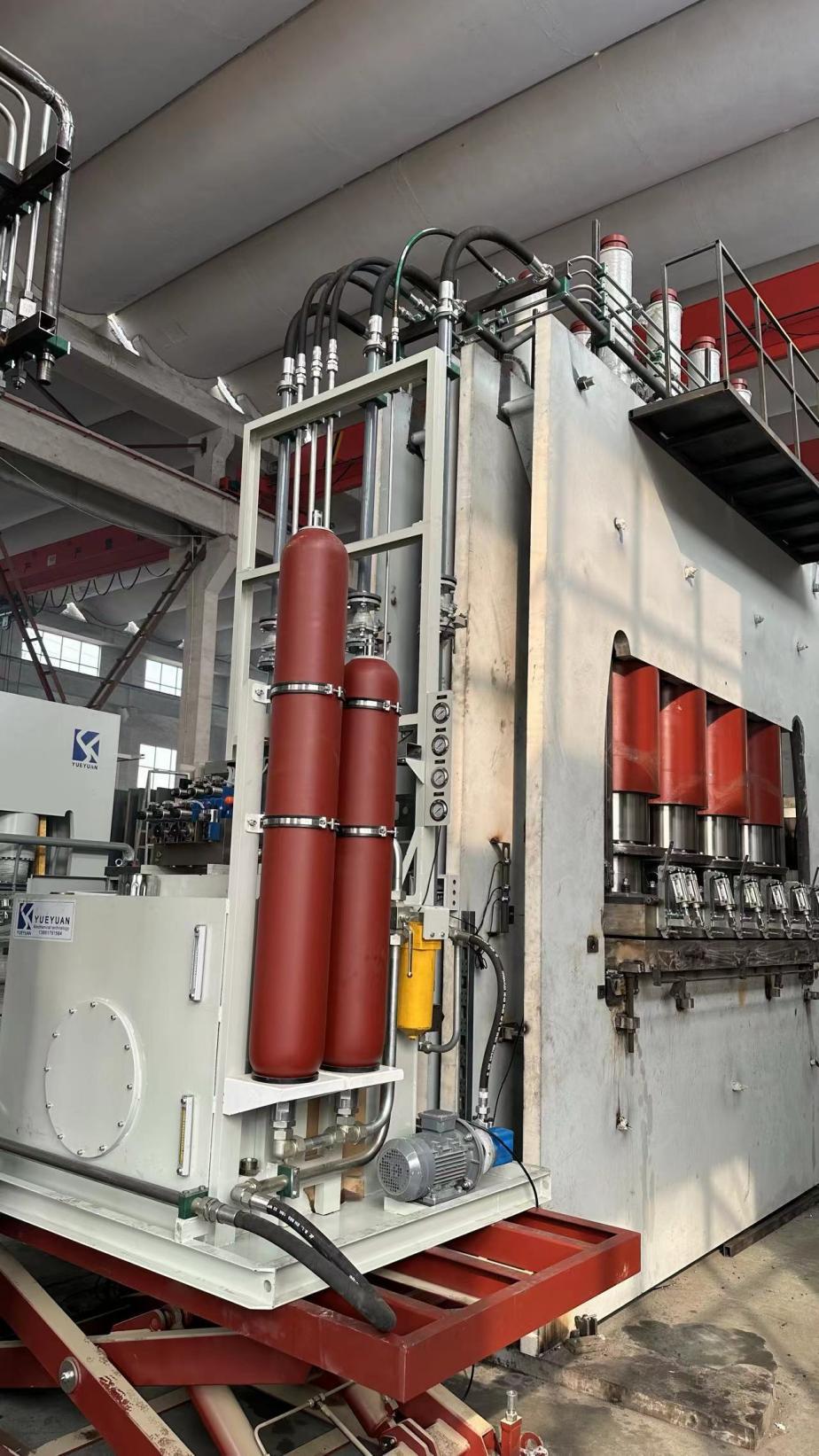

With the decrease in wood resources, especially precious wood resources, more and more furniture uses pressure processing, such as veneer or sticker application. Veneer presses, as important equipment for pressure processing, are frequently used in furniture manufacturing for single-layer boards and pressure-molded parts. Their production capacity and technical performance limit the production scale and product quality of enterprises. To better understand and select veneer presses, this article introduces the working principle of single-layer veneer presses commonly used in the furniture industry. In practice, the working principle of a veneer press is to apply positive pressure based on negative pressure and use special glue for processing. Veneer presses also feature high pressure, low temperature, and short film pressing time, solving the problem of workpiece deformation in negative pressure equipment processing, greatly reducing the degree of workpiece deformation, and ensuring product quality and performance.

The hot standby veneer presses currently available on the market can automatically complete the processing steps of entering, upgrading, heating, vacuuming, molding, demolding, and dropping the table. It is mainly driven by hydraulic pressure and compressed air, so there should be sufficient air pressure and volume. The frame is made of steel plates, and the overall structure is reasonable. The two workbenches can be recycled or used individually. Veneer presses are widely used in furniture production, wood doors, and factories that secondary process single-layer boards for artificial boards. Veneer presses can be considered one of the main machines in woodworking machinery. The main function of veneer presses in wood product processing is hot pressing and bonding furniture boards, building partition walls, wood doors, fire doors, and surface material finishes. PVC and other artificial boards, as well as the drying and flattening of single-layer boards and the flattening and molding of colored decorative boards, have very significant effects. The press mainframe can be divided into three parts: heating system (providing heat source), hydraulic system (providing pressure and controlling press actions), and press body (frame and control part). Generally, veneer presses are mainly evaluated and selected based on function, reliability, service, and price. This article mainly introduces the function and reliability of veneer presses.

There are not many production problems with the veneer press itself, but a large part comes from the hydraulic system, such as oil leaks and inability to maintain pressure. Much of the knowledge and requirements regarding hydraulic systems cannot be described here, but we must pay close attention when selecting.

The veneer press control system mainly controls the operation of the heating system and hydraulic system, and its sensitivity and accuracy directly affect the accuracy of the press operation. Due to the complex composition of the control part, it is often a part prone to problems. For complex presses, such as vacuum plating presses, many domestic press manufacturers directly import foreign control systems and try to minimize the use of low-reliability control components such as solenoid valves. Generally speaking, the functionality and reliability of veneer presses used in the furniture industry can be considered from the above aspects. Many single-layer board processing problems will occur during production, and they should be analyzed according to the specific situation.

Remind everyone to properly clean the veneer press for plywood to extend the service life of the veneer press. Therefore, we need to clean the veneer press regularly. Before cleaning the plywood press, the staff should make the corresponding cleaning preparations and turn off the power. The hot pressing area needs to be cleaned, which can effectively extend its service life. Check whether the switch connection is normal and whether there is any oil leakage. In addition, check for any abnormalities before starting operation every day.