Working principle of the laminating press

Published Time:

2023-01-17

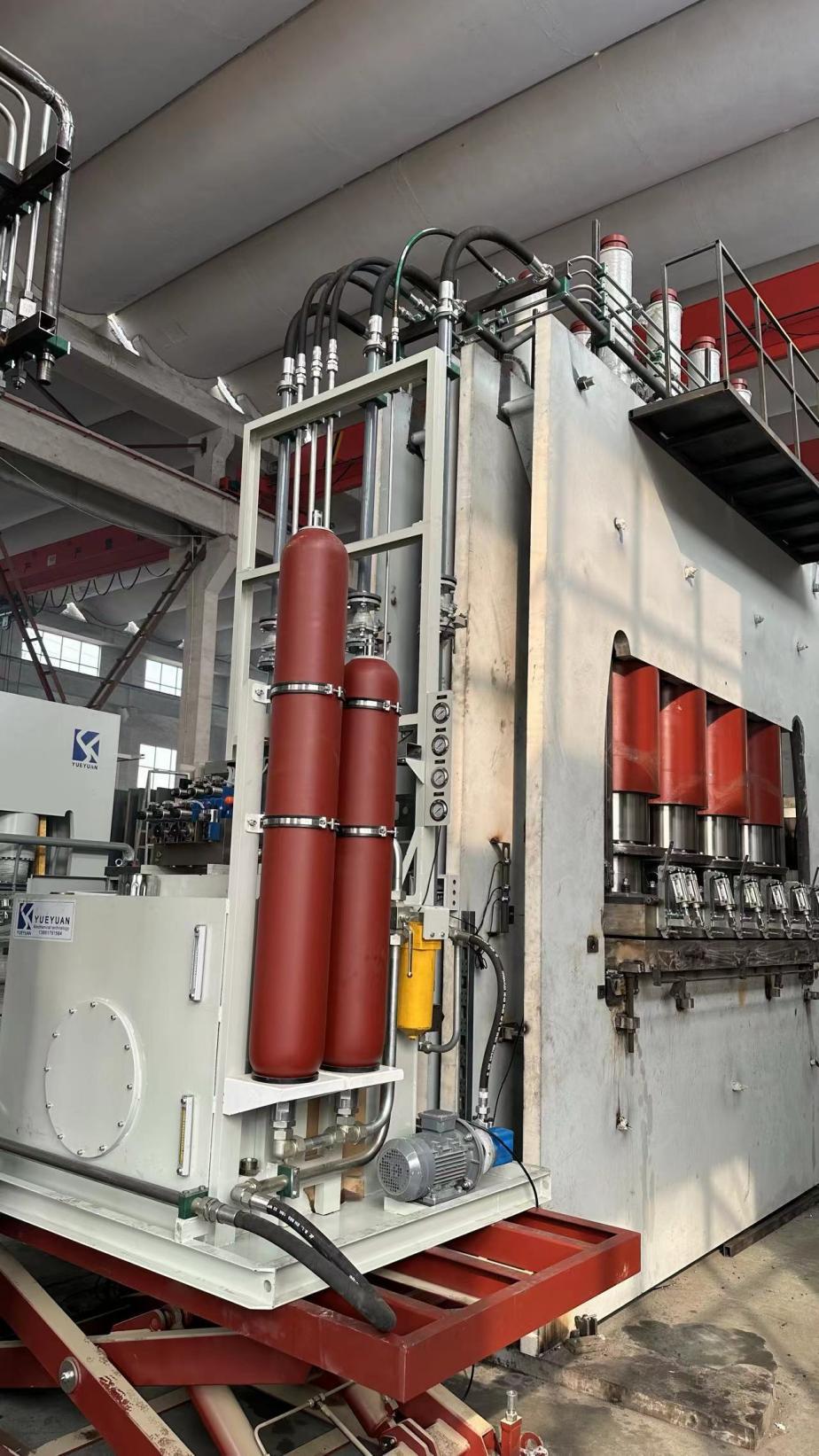

Working principle of veneer press With the reduction of wood resources, especially precious wood resources, more and more pressing and pasting processes, such as pasting veneer or stickers, are used in furniture. Veneer press, as an important equipment in the pressing process, is often used in furniture manufacturing to press and form parts

Working principle of veneer press

With the decrease of wood resources, especially precious wood resources, more and more pressing and pasting processes, such as pasting veneer or paper, are used in furniture. Veneer press, as an important equipment in the pressing process, is often used in furniture manufacturing to press and form parts. Its production capacity and technical performance restrict the production scale and product quality of enterprises. In order to better understand and select veneer press, this paper introduces veneer press taking the veneer press commonly used in furniture industry as an example. The veneer press used in furniture industry is basically applicable to the size of artificial board ( 1220×2440mm), and the surface pressure is generally 0.2~0.4MPa, and the corresponding total pressure is 120t. In addition to the main technical parameters such as the size, total pressure, number of layers and surface pressure of the hot press plate, there are other technical parameters such as opening and closing time, heating temperature and productivity, which should be determined according to different process requirements. The working process of veneer press can be divided into five processes: closing, pressurizing, maintaining, depressurizing and lowering. The host of the press can be divided into three parts in terms of function realization: heating system (providing heat source), hydraulic system (providing pressure and controlling the action of the press) and press body (frame and control part). Generally speaking, veneer press is mainly evaluated and selected according to its function, reliability, service and price. This paper mainly introduces veneer press from the aspects of functionality and reliability of veneer press.

1. Hot press heating system

( 1) Comparison of heating methods When using veneer press, the heating method will affect the selection of temperature, process control and the quality of processed products. The traditional heating methods are steam heating and electric heating. Steam heating is fast, but it needs a pressure boiler, the pipeline pressure is high,

steam is easy to condense into water, resulting in uneven temperature of the plate; electric heating has the advantages of fast heating speed, high heating temperature and easy control, but it has the disadvantages of high power consumption, high operating cost, resistance wire failure and difficult replacement. The advantages of heat transfer oil heating are: high heat capacity, uniform temperature, high temperature at room temperature, low heat loss and low production cost. Its disadvantages are slow heating speed and difficult temperature control. In the furniture industry, when the general requirements for hot pressing temperature are not high, the hot water circulating furnace can also achieve satisfactory results, and the fixed investment and operating cost are very low.

( 2) The performance of hot press plate can be evaluated from several aspects. First, the use of hot press plate material, then the processing precision, is the layout of the medium channel in the hot press plate. Hot press plates are generally made of a whole piece of pressed steel plate by deep hole drilling, mainly used for oil heating and steam heating; another is to paste aluminum plate on the back of welded pipe, mainly used for electric heating. The whole steel plate can avoid oil leakage caused by poor sealing, high rigidity and strength, but the hot press plate is thicker; the latter is usually in the form of thin plate, due to the stress generated in the welding and processing process, so it needs high processing precision. Thin hot press plate is easy to preheat and control temperature, but the requirements for processing parts are very high. Uneven workpiece thickness will cause plate deformation and affect the subsequent processing quality; thick hot press plate is beneficial to increase heat capacity and strength and stiffness, but it will increase the overall size of the press and consume more steel. In the manufacturing and processing process, the flatness of the hot press plate and the upper and lower surfaces should have sufficient parallelism. The flatness tolerance of the hot press plate should be in the range of 0.1-0.18mm, the parallelism tolerance should be in the range of 0.15-0.27mm, and the surface roughness of the press plate should be 3.2μm. The temperature difference of the whole width of the hot press plate should not exceed 2-3℃.