How is the hydraulic system of the veneer press?

Published Time:

2023-01-30

How is the hydraulic system of the veneer press? (1) Process requirements of the hydraulic system. The hydraulic system of the veneer press has two basic working requirements: applying pressure to the workpiece and driving the hot press plate to achieve specific movements. The rapid closing and stability of pressure maintenance are important indicators for evaluating the performance of the hydraulic system.

How is the hydraulic system of a veneer press?

( 1) Process requirements of the hydraulic system. The hydraulic system of a veneer press has two basic operational requirements: applying pressure to the workpiece and driving the hot press plate to achieve specific movements. The rapid closing speed and stability of pressure maintenance are important indicators for evaluating the performance of the hydraulic system. Since the heating and curing of the adhesive should be completed during the pressure holding stage of the single board, the fast closing speed is beneficial to the process and efficiency. On the one hand, it can reduce the heating of the slab under no pressure, prevent excessive water loss from the slab surface, thus causing warping, and also prevent pre-curing of the adhesive, thus reducing the quality of the single board; on the other hand, it can shorten the auxiliary time and improve the productivity of the press. In order to make the opening and closing of the press stable, mechanical synchronizers are usually set or hydraulic systems are used to maintain synchronization.

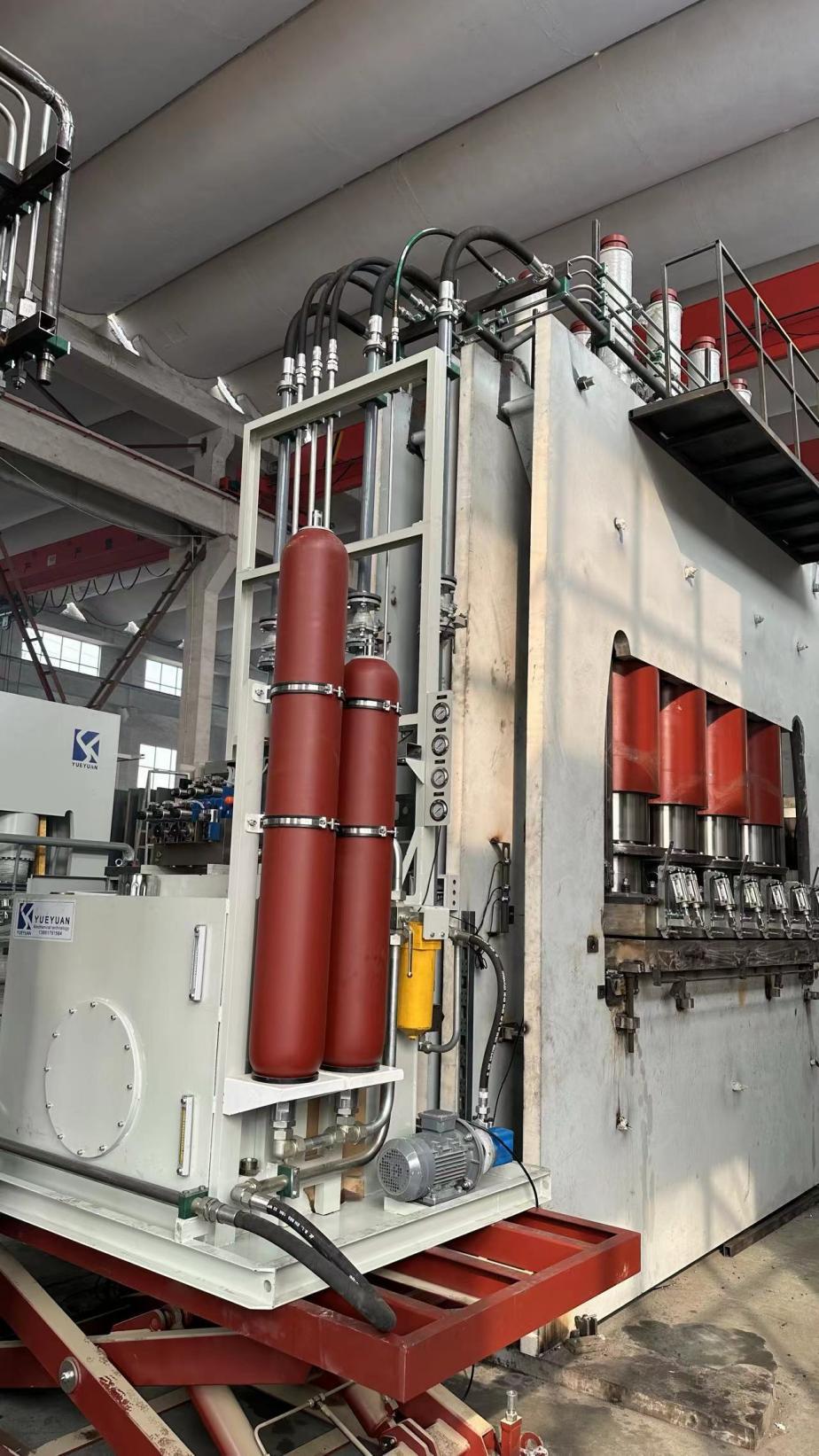

( 2) Hydraulic cylinder. The hydraulic cylinder is the core component of the hydraulic system. At present, most wood processing presses use plunger-type hydraulic cylinders. The plungers of large-diameter cylinders are mostly made of alloy castings, which are characterized by high hardness, thick hardness layer, scratch resistance, and better performance than carbon steel heat-treated plungers; small-diameter cylinder plungers are mainly carbon steel after hard chromium heat treatment, with a thinner surface hardness layer. Because veneer presses usually require fast opening and closing speeds to withstand impact pressure, the cylinder body must be made of high-strength materials. For ordinary hydraulic cylinders with small diameter and long stroke, seamless thick-walled steel pipes can be used. For some cylinders with higher requirements, cast or forged cylinders can be selected. Usually, the hot pressing worktable used in wood processing and furniture manufacturing is very large. In order to make the pressure distribution uniform and considering the rationality of the structural layout, a multi-cylinder structure is often adopted.

There are not many problems in the production of the veneer press itself, but a large part is caused by the hydraulic system, such as oil leakage and inability to maintain pressure. Many knowledge and requirements about hydraulic systems cannot be described here, but we must pay great attention when selecting them.

3. Veneer press control system

The control system of the veneer press mainly controls the operation of the heating system and the hydraulic system. Its sensitivity and accuracy directly affect the accuracy of the press. Due to the complex composition of the control part, it is usually a part that is prone to problems. For presses with complex functions, such as vacuum laminating presses, many domestic press manufacturers directly import foreign control systems and try to reduce the use of low-reliability control components in the press, such as solenoid valves. In general, the functions and reliability of presses used in the furniture industry can be considered from the above aspects. There will be many problems in the production of single-board processing, which need to be analyzed according to the specific situation. The use of appropriate connection methods and sealing elements is very important for heat transfer under high temperature and high pressure. At present, the connecting pipes of the hot press plate are mainly hoses, which makes the connection very convenient. In China, metal hoses are mainly used. Some manufacturers also use imported Teflon hoses, which can be connected to the flange in two ways. The fatigue resistance of PTFE hoses is better than that of metal hoses. The traditional gasket material is asbestos rubber sheet, PTFE and other new materials such as wound graphite have better sealing effect.