How to better demonstrate the application advantages of a single-layer press?

Published Time:

2023-02-01

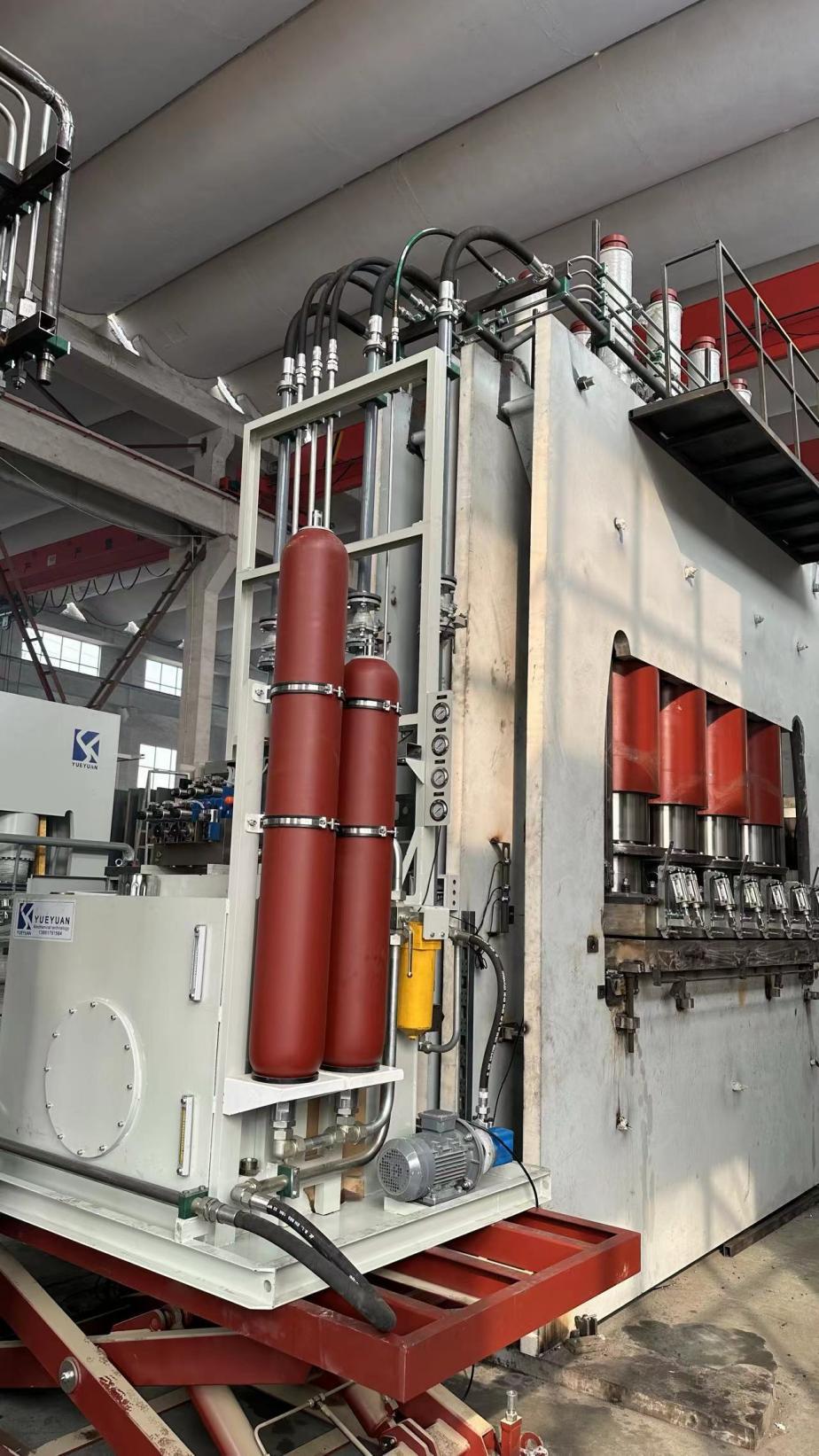

Based on the working principle of a single-layer press, through different process designs and reasonable design during manufacturing, the temperature can be effectively adjusted to achieve more ideal hot pressing effects in various production fields. The single-layer press, in terms of heating and power design, can meet the various usage requirements of these mechanical equipment. For current hot presses, they play an important role in the processing of plates to meet the actual selection and usage requirements of users. Let's share more below.

Based on the working principle of a single-layer press, through different process designs and reasonable design during manufacturing, the temperature can be effectively adjusted to achieve more ideal hot pressing effects in various production fields. The single-layer press's heating and power design can meet the various usage requirements of these mechanical equipment. For current hot presses, it plays an important role in the processing of sheet materials to meet the actual selection and usage requirements of users. Let's share more below.

Due to the large cutting and material utilization rate of the currently used single-layer press, and its simple and easy-to-use control operation, to meet actual usage requirements, appropriate tools and materials should be prepared for personnel and equipment during use and inspection. Lubrication of moving parts is also a very important task. By checking the temperature of the single-layer hot press and controlling and operating it reasonably, the actual requirements during the use process can be met.

In order to effectively improve the use efficiency and extend the service life of hot pressing equipment, and reduce production costs while providing production guarantees for users, users must currently prepare for a certain amount of preheating when using the hot press. Meeting the actual temperature requirements is a very important part of production processing. By performing a simple inspection of the single-layer press, faults or problems that may occur during use can be prevented, and maintenance is particularly important.

According to user requirements, products can be cut to non-standard sizes and different specifications to meet the diverse needs of users. However, single-layer press products only come in different specifications. Single-layer presses bear a lot of pressure during sheet metal forming, especially when the thickness of the packaging board is uneven. The pressed products will deform into an arc shape due to uneven pressure, so stricter use of the equipment is required.

Single-layer presses have a low failure rate, long equipment life, and low maintenance costs during operation. The produced products are suitable for various width specifications. Combined with the automatic testing of the hot press, automated production becomes simple. Among them, the use of a single-layer press can ensure uniform density distribution without affecting the thickness tolerance of the sheet material.

For hot presses, regular use of lubricating oil can extend the life of the fully automatic saw and ensure smooth operation under subsequent mechanical actions. Lubricating oil is also a way to maintain and maintain a single-layer press.

Thin oil, through cooling or isolation of components that generate a large amount of heat, such as the surface of sawtooth mechanical components, can prevent the generation of excessive heat during friction and lead to rapid wear and deformation.

Oil mist. Lubrication is achieved through airflow. In the airflow process, a small amount of oil droplets attached to the pipe wall are sprayed onto the friction surface, which is an economical and commonly used method.

Oil mist. This method distributes the oil in a mist-like manner on the friction surface, making efficient use of the lubricating oil, and is a micro-lubrication method.