Features of single-layer press machines and how to set different temperatures for specific models

Published Time:

2023-02-16

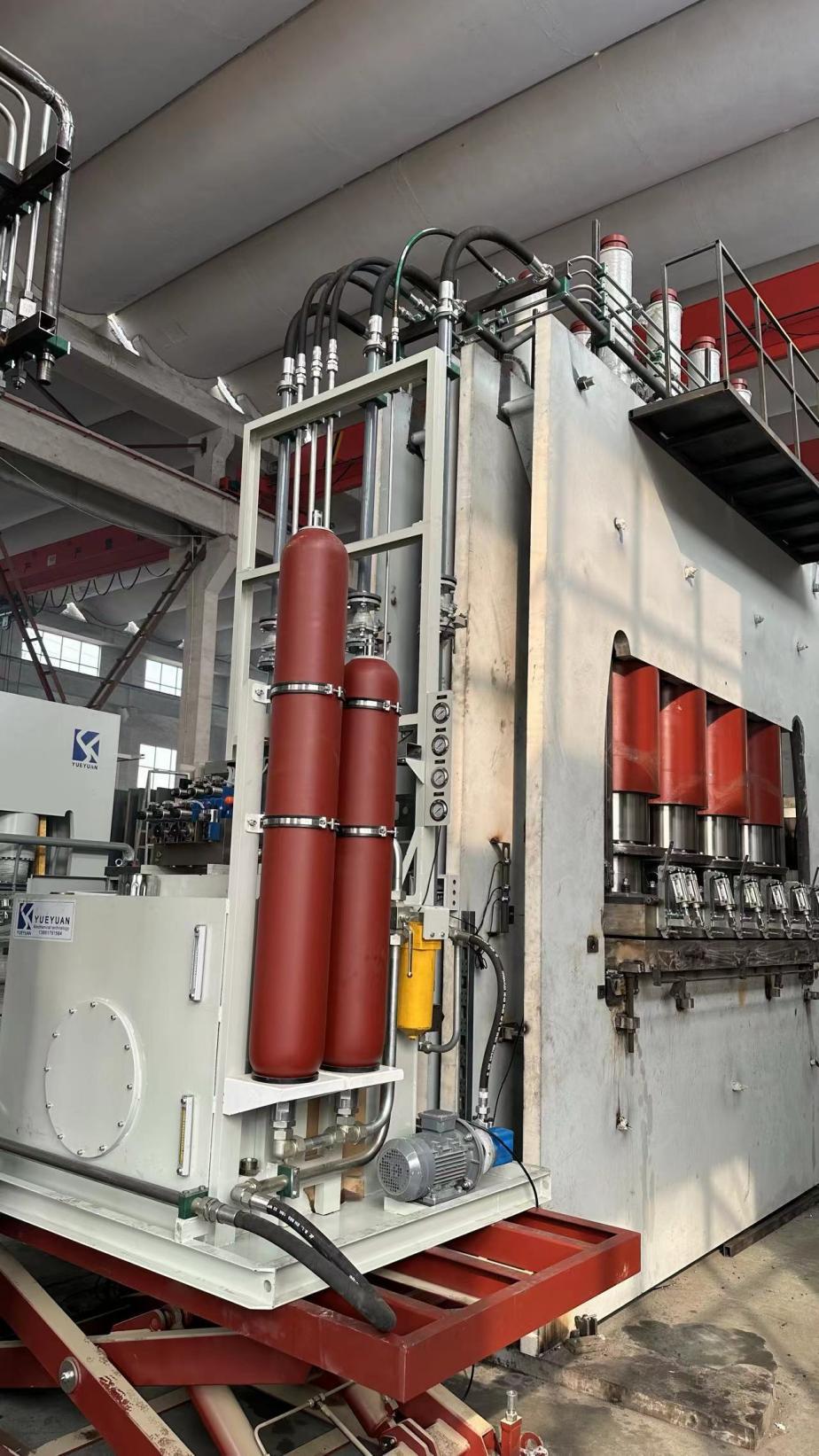

A single-layer press involves a double-layer hot press that can simultaneously hot press multiple products. A single-layer hot press consists of an upper hot press plate and a lower hot press plate, which heat and press the slab. It is one of the important equipment for artificial board manufacturing and surface treatment.

Single-layer press This involves a double-layer hot press that can simultaneously hot press multiple products. A single-layer hot press consists of an upper hot press plate and a lower hot press plate, which heat and press the slab. It is one of the important equipment for artificial board manufacturing and surface treatment.

I. Main Development Characteristics of Single-Layer Press

(1) The corresponding working speed is fast, and the heat can be concentrated well. The spacing is also small, and the output temperature and other heating parameters can be reasonably set.

(2) The machine equipment has fault diagnosis and alarm functions such as abnormal temperature disconnection, preventing problems such as workpiece burning or equipment damage.

(3) Hot pressing has a variety of heat settings and a relatively wide time range, so some complex welding processes can be used. It is also very convenient and simple in display and operation.

II. Main Development Advantages of Single-Layer Press

For a single-layer hot press in a single-layer press, the advantages are: for operation and control, the operator only needs to focus on one plate. In addition, if there is an automatic detection function, it can meet the needs of automated processing and production, and improve production efficiency.

III. Single-layer press temperature setting

If a single-layer press is used for melamine paper, the temperature setting is generally about 20 degrees higher than the material temperature. As for the heating equipment, mechanical heating and electric heating mold temperature control can be used. Because the heating effect is good, the temperature setting is convenient.

A single-layer press is a device that heats two pre-soldered tin-plated parts to a temperature sufficient to melt and flow the solder, and after solidification, forms an electromechanical connection between the parts and the solder. The heating rate can be selected according to different products.

The titanium alloy press head ensures even temperature, fast heating and long service life. The press head adopts a horizontally adjustable design to ensure even pressure on the components. The temperature is digitally controlled, clear and precise. It is equipped with a digital pressure gauge, which can preset the pressure range. Check the heating, lubrication, and transmission of each motor, reducer, and bearing every 4 hours, and whether the travel switch and pneumatic components are working normally. For each car plate, pay attention to whether the accumulator is charged normally. Always pay attention to whether there is any jamming phenomenon between the press plate and the beam and the frame when the press rises. If there is any, the fault should be eliminated in time.