Introduction to the advantages and disadvantages of a single-layer press

Published Time:

2023-02-22

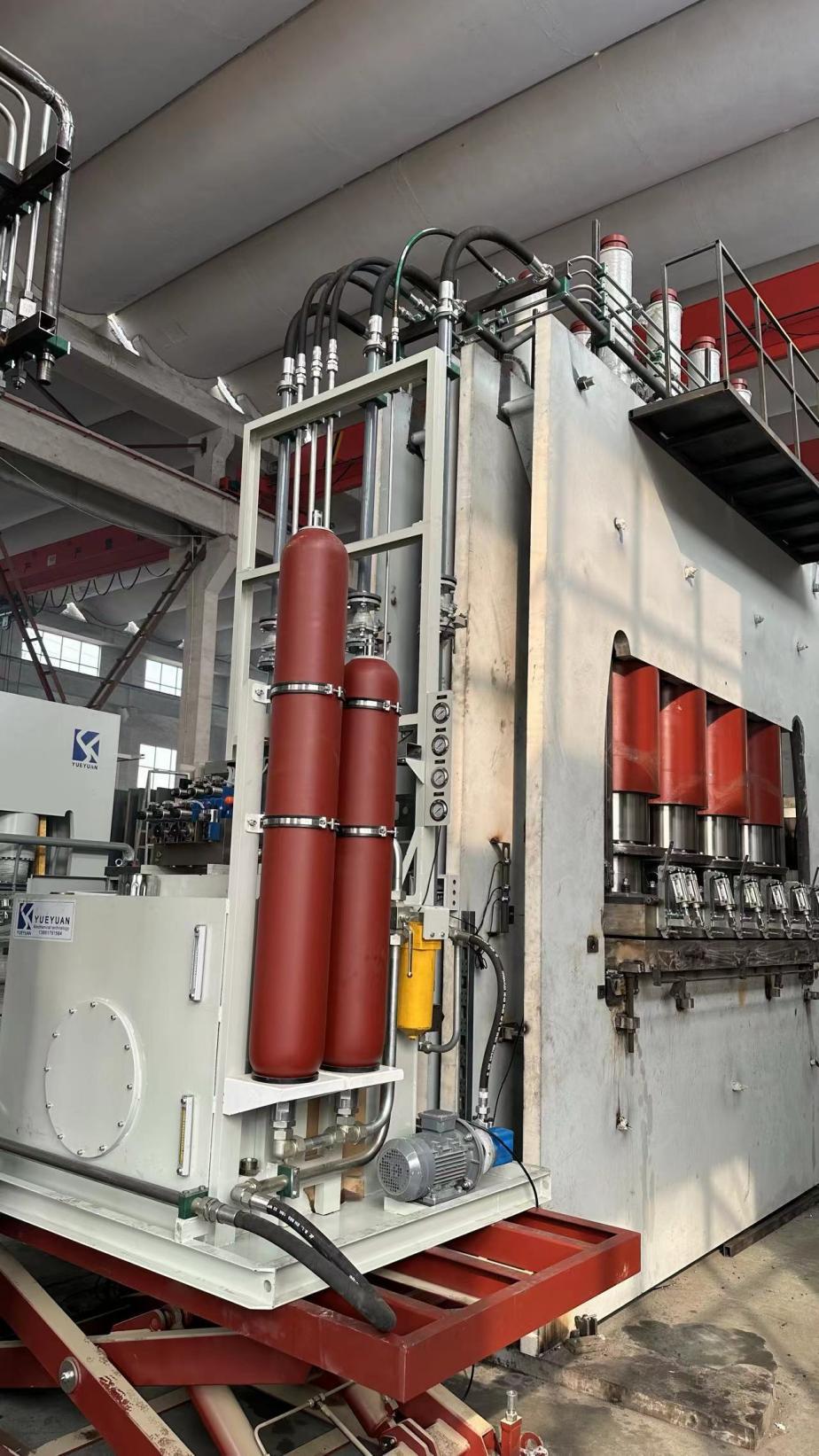

Compared with multilayer hot presses, single-layer presses have many advantages. First of all, multilayer presses have large openings, long clamping time, long auxiliary time, and long clamping time of the broken plate in the hot plate, resulting in a thick prepreg layer, large consumption, and a lot of grinding; while single-layer presses have small openings and short auxiliary time. The time is short, the prepreg layer is thin, and the amount of grinding is small.

Compared to multilayer hot presses, single-layer presses have advantages in many aspects. First, multilayer presses have large openings, long clamping time, long auxiliary time, and long clamping time of the broken plate in the hot plate, resulting in a thick pre-cured layer, large consumption, and a lot of grinding; while single-layer presses have small openings and short auxiliary time. The time is short, the pre-cured layer is thin, and the amount of grinding is small. Calculated with a 16mm plate thickness, the sanding amount is only one-third of that of a multilayer press. Single-layer presses are simple to control and operate; operators only need to focus on one slab; if one slab is improperly operated, it will inevitably affect the working cycle or produce defective products. In addition, with the perfect automatic detection of single-layer presses, it easily meets the needs of automated production without human control;

Secondly, the products produced by single-layer presses are large-format specifications, which can be cut into non-standard sizes and different specifications according to user needs to meet the diverse needs of users; while the product specifications of multilayer presses are single; the slabs of single-layer presses are laid on metal belts, the transportation distance is short, and no pre-press is used. The slabs and belts directly enter the hot press, and the slabs are not easily damaged during laying, and the finished slabs do not deform; however, multilayer presses have a long transportation distance, requiring multiple conveyors to be switched and hot press loading procedures. Poor symmetry can lead to warping and deformation; because the single-layer press has a large format and a large footprint, but because there is no pre-press, some conveyors and loaders are also needed, so the length of the entire paving machine will not be too long.

Then, the failure rate is low, the parts have a long service life, and the maintenance cost is low; compared with single-layer presses, the edge cutting loss of multilayer presses is greater than that of single-layer hot presses, and the material utilization rate is low. Because each finished plate of a multilayer hot press needs to cut four sides, while a single-layer press only cuts the entire width and four sides. Generally, for a production line with an annual output of 50,000 cubic meters, the blade wear of a multilayer press is 3.5 times that of a single-layer press.

1. Using pulse heating technology, the temperature control is accurate, and the temperature sampling frequency is 0.1s.

2. Various working modes such as single working platform, rotating working platform, and left-right moving platform.

3. Multi-stage temperature control.

4. Real-time temperature curve display.

5. Silicone belt indexing mechanism.

6. CCD vision system, providing accurate positioning.

7. Large capacity program storage.

8. Touch operation interface, program password protection.