Structure and function of a single-layer press

Published Time:

2023-02-28

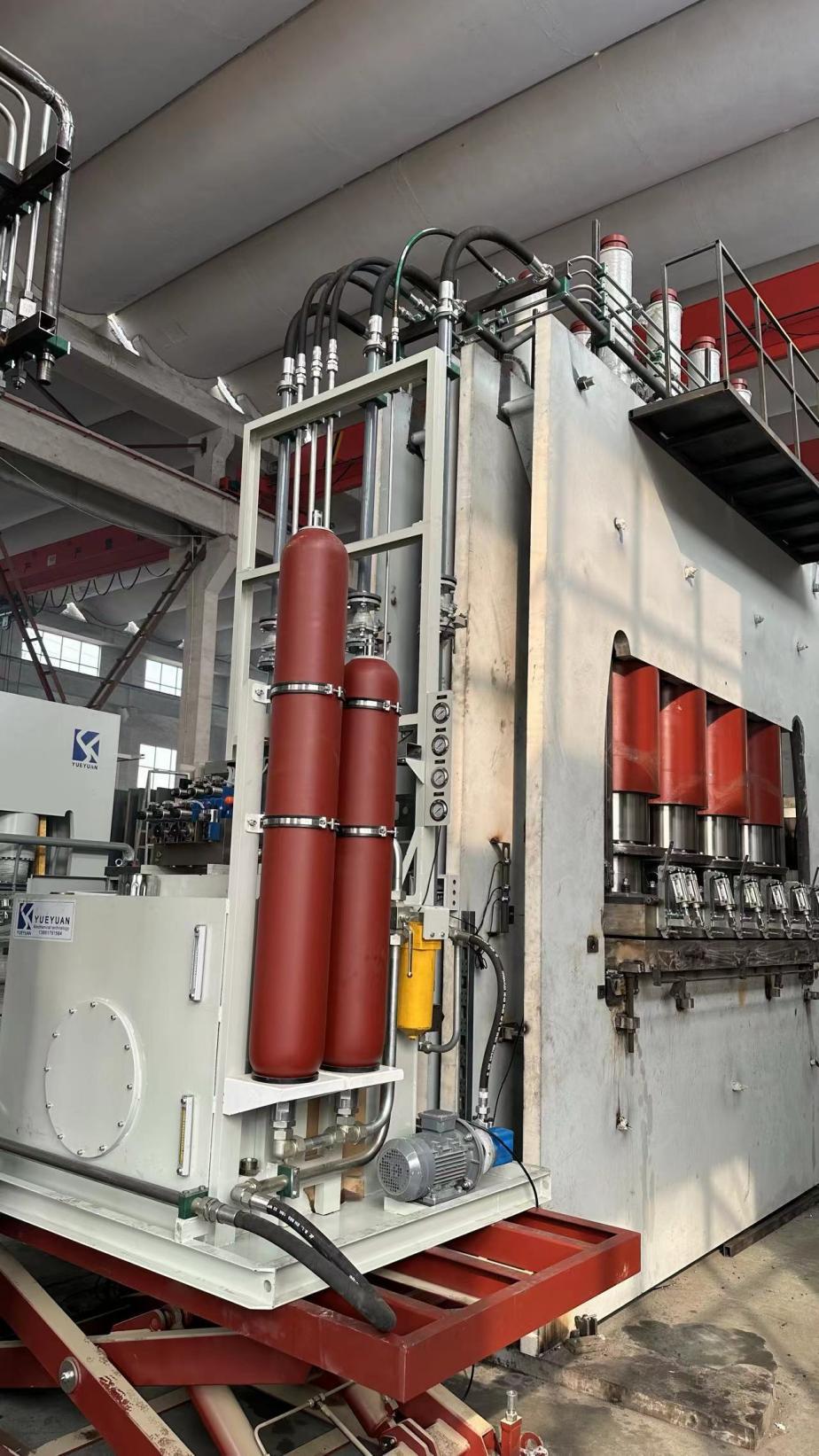

The single-layer press loading and unloading system consists of a sealing head, loading rack, oil tank, oil cylinder, solenoid valve, etc. Its main function is to lift and lower the sealing head that carries the product using a pneumatic-hydraulic device as the power source. The lifting action of the sealing head is controlled by a manual directional valve. The system lifts and lowers smoothly and vertically, which is conducive to sealing between the sealing head and the sealing container.

Single-layer press The structural system mainly includes four parts: loading and unloading system, heating system, pressure system and protection system.

The single-layer press loading and unloading system consists of a sealing head, a loading rack, an oil tank, an oil cylinder, a solenoid valve, etc. Its main function is to lift and lower the sealing head carrying the product using a gas-liquid device as the conversion power. The lifting action of the sealing head is controlled by a manual reversing valve. The system lifts and lowers smoothly and vertically, which is conducive to the sealing between the sealing head and the sealing container.

The single-layer press heating system consists of measuring elements, a controller and a heater. Its function is to control the temperature increase and constant temperature of the water in the container. Heat is transferred to the pressurized capacitor rod through water, making it uniformly heated. The rod becomes soft when heated, which is not only conducive to compression, but also avoids cracks caused by compression.

The single-layer press heating element is a stainless steel electric heating plate wrapped around the outer surface of the closed container. When energized, the electric heating plate heats up and transfers heat to the water in the container, causing it to heat up. In practice, in order to ensure that the water temperature meets the process requirements, it is usually heated before feeding, and a temperature detector is equipped to directly measure the water temperature. During operation, the container is closed under high pressure, and the water temperature can only be measured and controlled by an intelligent digital temperature controller. The temperature measuring element cannot directly measure the liquid temperature in the container, but can only measure indirectly. Therefore, when selecting and installing the element, the measurement error and control hysteresis need to be minimized.

The pressure system consists of a pressure transducer, a pressure control instrument, a booster pump, a manual valve, a pneumatic valve, etc. Its main function is: the pressure transducer detects the pressure inside the sealed container, converts the pressure value into a 4~20mA standard signal, and transmits it to the signal input end of the pressure control instrument.

The pressure control instrument is the control core of the pressure system. It receives the pressure signal from the pressure transducer and controls the output according to the received pressure signal.

The signal output by the pressure control instrument controls a set of pressurizing components, and the system pressurizes the inside of the closed container through these components.

The booster assembly is a complex and critical component, consisting of a solenoid valve and a booster pump. The booster pump continuously injects water into the closed container, causing the water pressure in the container to continuously increase until the pressure set value is reached.

When the pressure reaches the set value, the booster pump stops working, the system enters the shutdown and constant pressure state, and starts timing. During the constant pressure process, the system can automatically compensate for the pressure drop, keeping the pressure within a more precise range.