What is a single-stage compressor?

Published Time:

2023-03-06

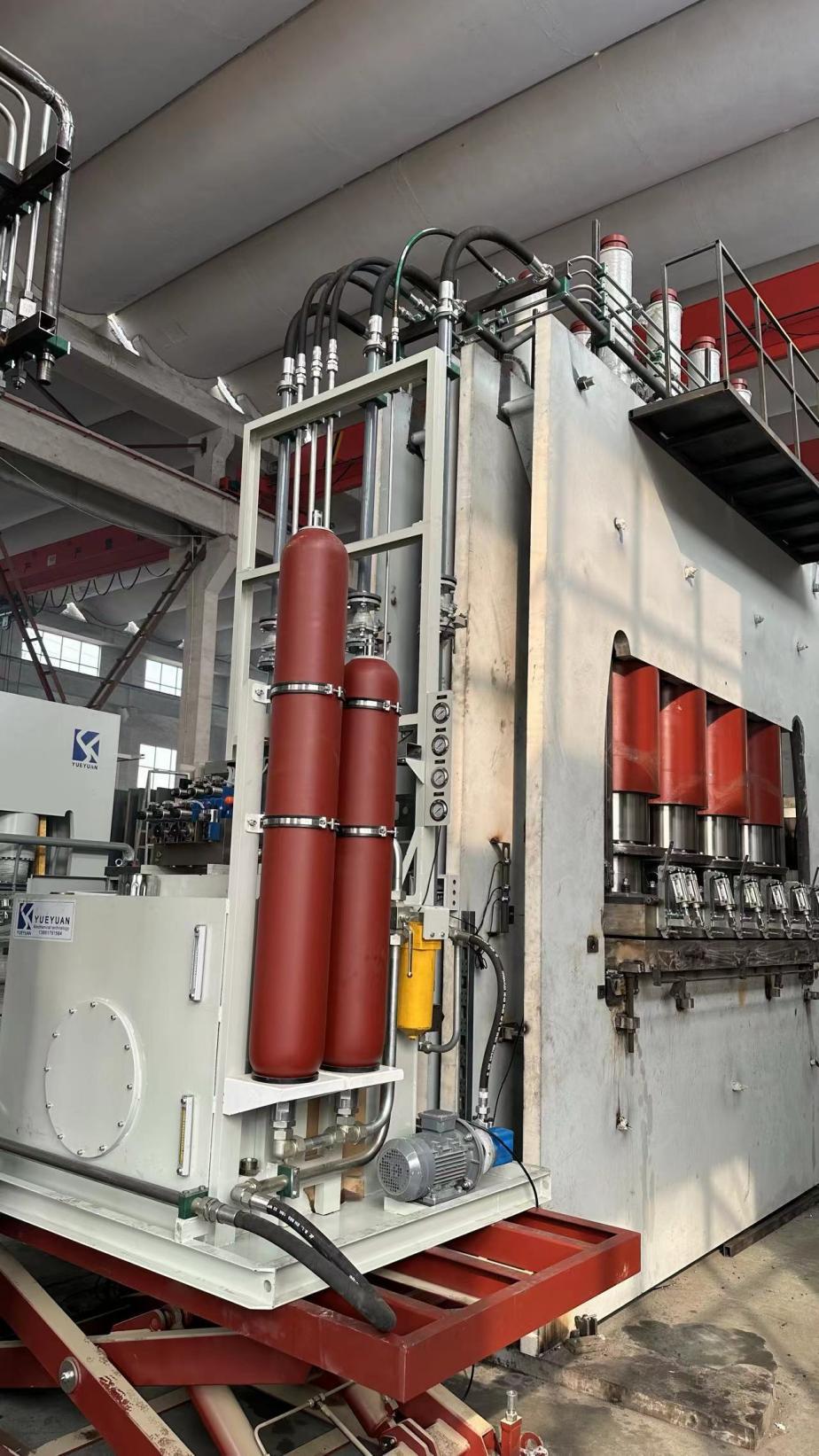

A single-layer press is a mechanical device that presses multiple layers of material together. A press with a floating platen is installed between the moving platen and the fixed platen, i.e., a press with three or more hot platens.

Single-layer press Refers to mechanical equipment that presses multiple layers of materials together. A press with a floating pressure plate is installed between the moving pressure plate and the fixed pressure plate, i.e., a press with three or more hot pressing plates.

The single-layer press is one of the specialized production equipment for multilayer ceramic chip capacitors. Its function is to apply the principle of uniform pressure transmission of water, forming a high-pressure system by pressurizing the water in a sealed container, and uniformly applying pressure to the capacitor chips placed in the water, making its structure compact and surface smooth to meet the production process requirements. According to the process requirements, the prepared ceramic dielectric slurry is injected onto the steel belt of the casting machine, and then the casting is dried into a thin film, becoming the dielectric material (ceramic dielectric thin film) of the capacitor; then, using precise multilayer screen printing technology, the inner electrode is repeatedly printed on the ceramic dielectric film, each layer is pressed by the pressure platform, and then printed into a component block.

In order to make the rod structure compact, the rod is packaged in a plastic film bag, vacuumed and sealed, placed in hot water in a container, the container is sealed and pressurized to over 30Mpa. After the components are uniformly compressed in water, their loose structure becomes uniformly compact, ensuring the consistency of the electrical performance indicators of the components, and effectively improving product quality.

No matter what operation the single-layer press is applied to, its working principle is the same. That is, a certain pressure is applied to the surface of the multilayer material to press these materials tightly together. The difference lies in that the lamination conditions vary depending on the lamination purpose.

The key point in the lamination process is pressure control. The greater the pressure, the better the product quality. The specific requirements are: the pressure rise must be stable, the pressure control accuracy must be high, the constant pressure time must be precisely controlled, and the pressure in each direction of the product must be uniform. In order to meet the requirements of the lamination process and product production, the main design of the equipment should include four parts: loading and unloading system, heating system, pressure system, and protection system. Based on the above ideas, the working process of the laminator design is:

1) Heat the water in the container to a constant temperature; 2) Product loading, the sealing head descends; 3) Set the working pressure, constant pressure time, apply pressure and maintain pressure; 4) Automatic pressure relief after pressure holding; 5) The sealing head rises, and the product is taken out.

The function of the single-layer press is to press these substances together. After pressing, the following purposes need to be achieved: 1. No bubbles after pressing (<2/㎡) 2. The mixed substances should be integrated 3. There must be a certain bonding strength between incompatible substances. In order to achieve these three goals, the process requirements must be met in the following aspects: a, pressure b, temperature c, vacuum degree d, time.