The process and principle of a multilayer press

Published Time:

2023-03-14

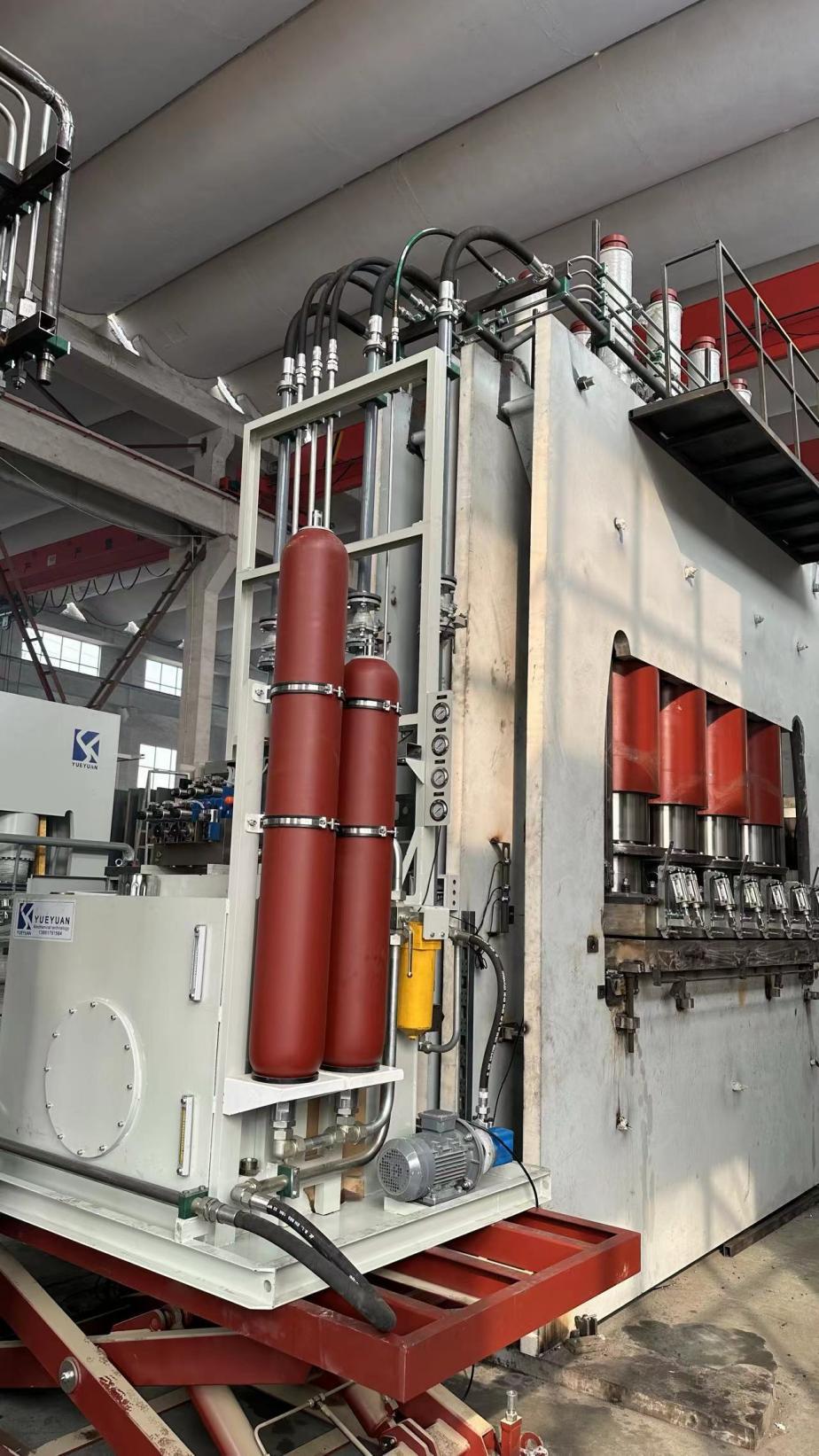

Regardless of the operation, the working principle of a multilayer press is the same. That is, a certain pressure is applied to the surface of the multilayer material to press these materials tightly together. The difference is that the pressing conditions vary depending on the purpose of lamination.

Multilayer Press It is a mechanical device that compresses multiple layers of materials together. What is the process and principle of a multilayer press?

According to process requirements, the prepared ceramic dielectric slurry is injected into the steel strip of the casting machine. After casting, drying, and film removal, it becomes a capacitor dielectric material. The inner electrode is repeatedly printed on the ceramic dielectric film, and each layer is pressed by a pressing table to form a component rod.

In order to make the structure dense, it is placed in a plastic film bag, sealed after vacuuming, placed in hot water in a container, and the container is sealed and pressurized to over 30 MPa. After the component is uniformly pressurized in the water, its inherently loose structure becomes more uniform and dense, ensuring the consistency of the electrical equipment performance analysis indicators and effectively improving the quality of the enterprise's products.

No matter what operation the multilayer press is used for, its working principle is the same. That is, a certain pressure is applied to the surface of the multilayer material to press these materials tightly together. The difference is that the pressing conditions are different depending on the purpose of lamination.

Precautions for using a multilayer press

1. Reasonable selection of a multilayer press: When selecting a multilayer press, factors to consider include the area of the multilayer press. A highly compatible area should be selected, while also considering factors such as the opening method and appearance. Use as many machines as possible. After selection, install and debug under the guidance of the manufacturer and put it into normal production.

2. After the multilayer press completes the self-check in the standby state, it can enter the working state.

3. Operating system program: Press the vacuum pump start button - check the construction process parameters - check the temperature and whether the time setting value is reached - check whether the working state is automatic or manual, set an automatic control state - check whether the vacuum pump is lacking oil - place the components to be laminated - close the lid - check the vacuum degree - remove the components - check the main components. Under the condition that all processes are normal, the multilayer press enters the normal working state.

4. Multilayer pressing shutdown time: The shutdown time required to turn off all power supplies for multilayer pressing. To ensure that information is not misused by non-operators, the emergency button can be included in the shutdown range. The operating procedure is as follows: Vacuum pump off - close the lid (do not close the lid) - heating off - power off - press the emergency button - close the main gate or press the emergency button - close the main gate.

5. Usage method after the multilayer press is idle for a period of time: After the multilayer press is idle for a period of time, it should be started according to the normal application program. Do not put in the battery panel. First, run the machine empty for two cycles to remove the moisture adsorbed in the machine before normal use.