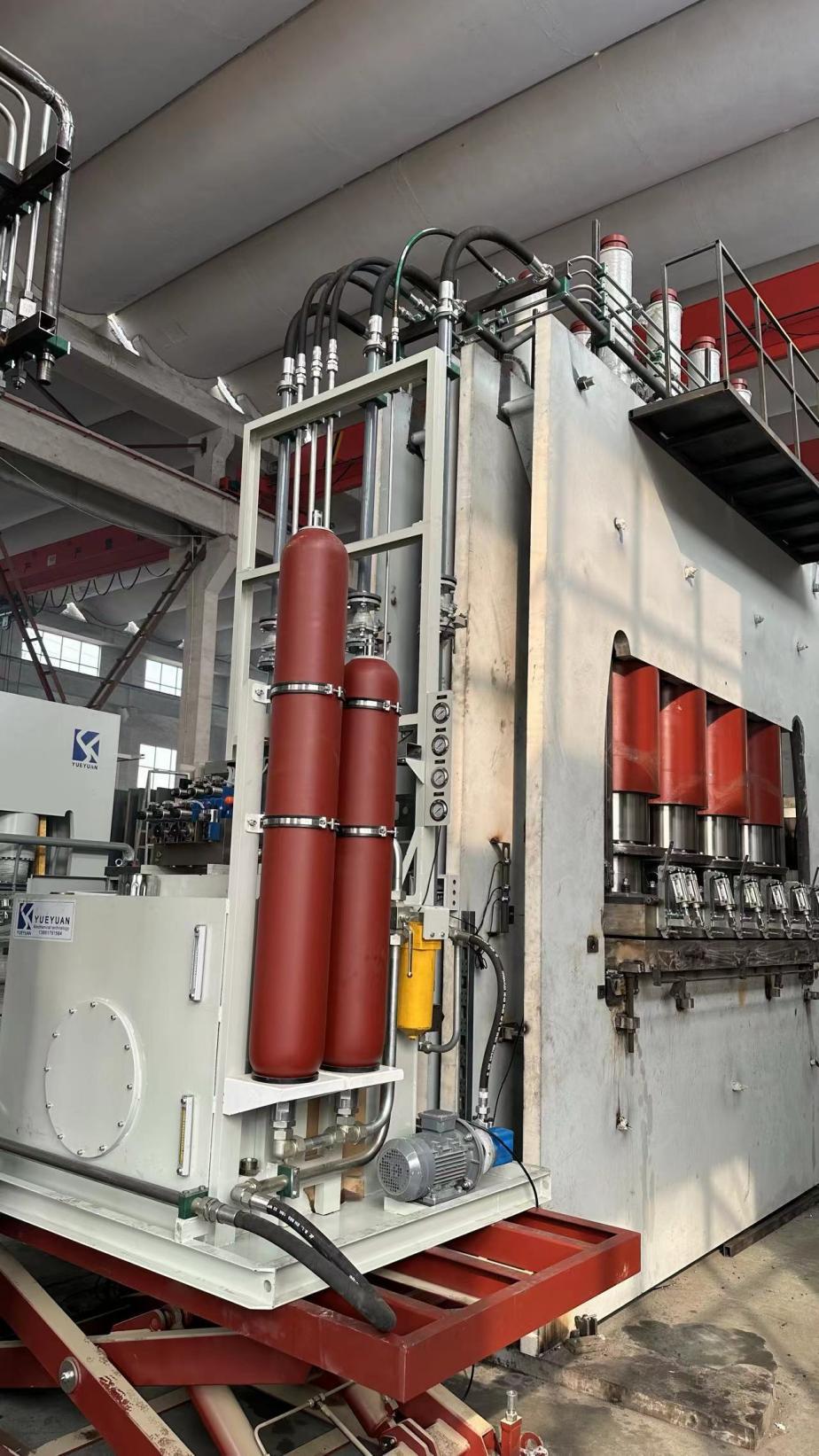

How to maintain and service a multilayer press

Published Time:

2023-03-20

Use the release cloth normally. Manufacturers always place two pieces of release cloth on the multilayer press, reminding the importance of using release cloth from different manufacturers in production. The function of the release cloth is to isolate the melted EVA from sticking to the upper chamber rubber plate and the multilayer press heating plate. Once the EVA sticks to the rubber plate and the heating plate, it will be difficult to remove.

1. Normal use of fiberglass cloth. Manufacturers always Multilayer press Place two pieces of non-stick cloth on the machine, reminding the importance of using non-stick cloth from different manufacturers in production. The role of non-stick cloth is to isolate the melted EVA from the upper chamber rubber plate and the multilayer press heating plate. Once the EVA sticks to the rubber plate and heating plate, it will be difficult to remove.

The correct management method is: at least 4 non-stick cloths are needed for one multilayer press. After each use, do not reuse it immediately, but put it aside and wait until the non-stick cloth cools down completely before removing the EVA completely. If the EVA cannot be completely removed from the laminated cloth, the EVA will stick to the battery glass upon reuse. No matter what is used to clean it, EVA particles will remain on the glass. When the battery panel is used outdoors, these EVA particles will remelt and stick to the glass, attracting dust and becoming impossible to remove.

2. Correct use of frame sealing materials. When the battery panel is installed in the frame, sealant is required. Some companies press the EVA strip into the concave groove of the frame without sealing it and use a hair dryer to melt the EVA. If EVA is used for frame sealing, be sure to cure it in a curing oven after the panel is added to the frame. Otherwise, when used outdoors, the EVA will repeatedly melt and absorb a large amount of dust under sunlight. In addition, the sealant must not be colored, otherwise the pigment will slowly spread to the EVA in the battery panel, and the battery panel will discolor after one year of use.

3. Normal use of the vacuum pump. In the daily maintenance of the multilayer press, the maintenance of the vacuum system is the most important part. After a period of time, the vacuum degree of the multilayer press will decrease. When it decreases to a certain level, the battery panel will have a large number of bubbles. Therefore, it is necessary to check whether the vacuum pump is lacking oil every day. Under working conditions, check whether the vacuum pump oil level reaches the window oil level line. When the oil level is insufficient, it should be replenished in time, but not excessively. Secondly, after a period of time, the oil in the vacuum pump becomes turbid or black, at which time the vacuum pump oil needs to be replaced, and the vacuum pump should be cleaned at the same time. When cleaning, the vacuum pump sucks in colloidal foreign matter.