Structure and function of a multilayer press

Published Time:

2023-03-24

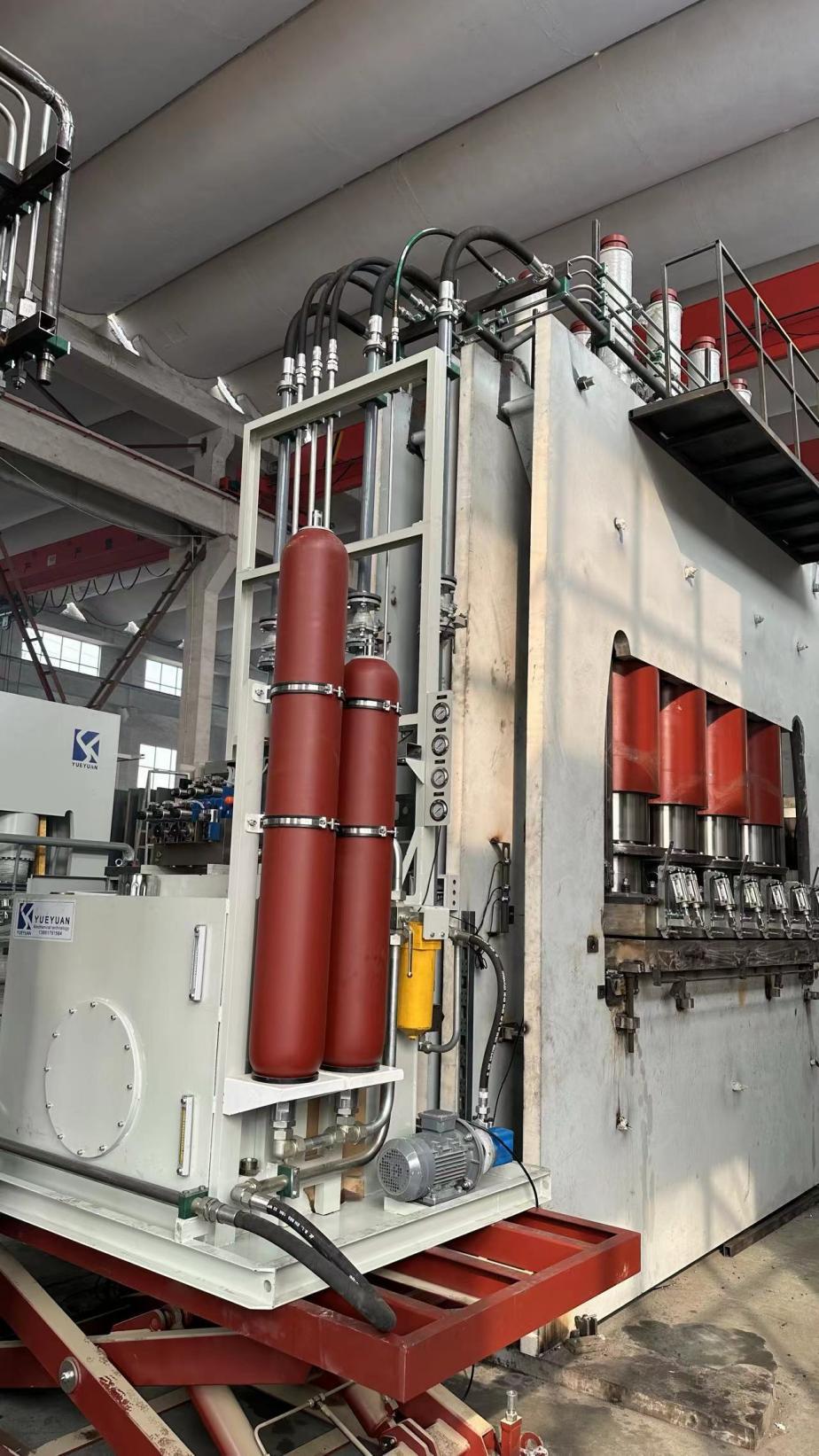

The loading and unloading system of a multi-layer press consists of a sealing press head, a loading rack, a hydraulic tank, a hydraulic cylinder, a solenoid valve, etc. Its main function is to use a pneumatic-hydraulic device as a power conversion device to lift and lower the sealing press head carrying cultural products. The lifting and lowering action of the sealing press head is controlled by a manual reversing valve. This system is stable and vertical during lifting and lowering, which is conducive to sealing between the sealing head and the sealing container.

Multi-layer press The structural system mainly consists of four parts: feeding and discharging system, heating system, pressure system, and protection system.

1. Loading and unloading system. The loading and unloading system of the multi-layer press consists of a sealing press head, a loading rack, an oil tank, an oil cylinder, a solenoid valve, etc. Its main function is: using a gas-liquid device as the conversion power, lifting and lowering the sealing press head carrying the product. The lifting and lowering action of the sealing press head is controlled by a manual reversing valve. This system lifts and lowers smoothly and vertically, which is conducive to the sealing between the sealing head and the sealing container.

2. Heating system. The heating system of the multi-layer press consists of measuring components, controllers, and heaters. Its function is to control the heating and constant temperature of the water in the container, and the heat is conducted to the capacitor plates being compressed through the water, so that they are heated evenly. The softening of the plates due to heating is conducive to compression and effectively avoids cracks during compression.

3. Pressure system. The pressure system consists of a pressure transmitter, a pressure control instrument, a booster pump, a manual valve, a pneumatic valve, etc. Its function is: the pressure transmitter detects the pressure in the sealed container, converts the pressure value into a standard 4~20ma signal, and transmits it to the signal data input terminal of the working pressure control instrument.

The signal output by the pressure control instrument can control a pressurizing component. The system mainly pressurizes the inside of the sealed container through the pressurizing component.

When the pressure reaches the set value, the booster pump stops working, and the system enters a closed constant pressure state and starts timing. During the constant pressure process, the system can automatically compensate for the pressure drop, so that the pressure can remain constant within a relatively accurate range.

When the system constant pressure is completed, the pressure control instrument sends a pressure relief signal to control the pneumatic valve to release the pressure, so that the water in the closed container leaks out, and the pressure in the container decreases accordingly.

4. Protection system. The protection system mainly includes the protection of lifting and lowering actions, heating, and pressurization.

(1) A safety door microswitch is installed at the product loading location, and the multi-layer press can only start working after the safety door is closed.

(2) When the sealing press head descends to a suitable position, it triggers the travel control switch. Four cylinders simultaneously perform locking actions, and four travel switches are triggered separately before the pressurization system starts pressurization.

(3) The heating protection device is equipped with over-temperature and low-temperature alarm devices.

(4) The water pressure gauge itself has a pressure limiting function. The limit value range can be determined by adjusting the limit pointer on the dial. If the pressure cannot rise to the lower limit of the set value or exceeds the upper limit of the set value within the specified time, the alarm bell will sound.