One-minute introduction to multilayer press

Published Time:

2023-03-30

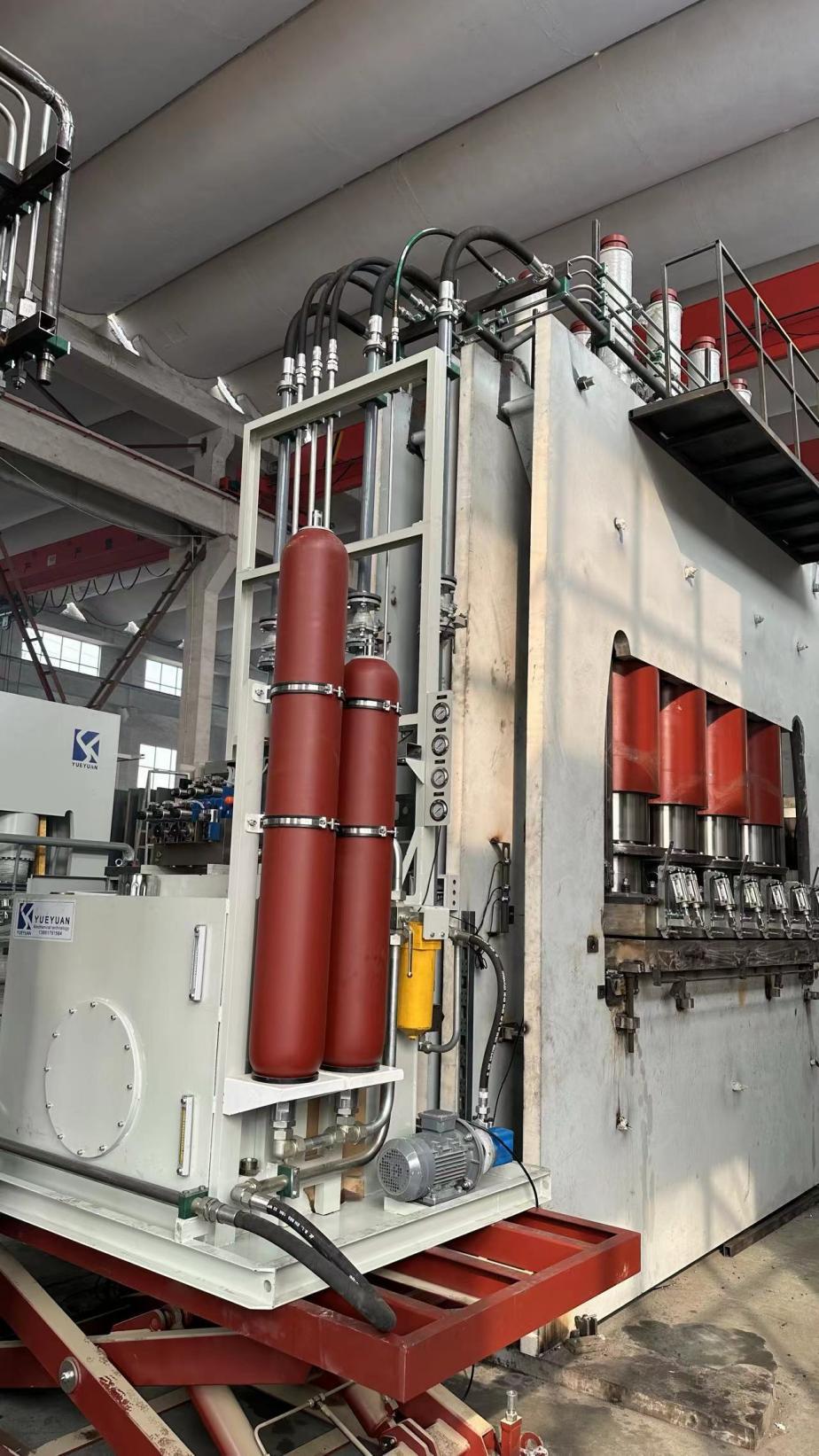

A multilayer press is a relatively common three-dimensional pressing equipment currently available. Its principle is to transform the pressing material into the desired shape under certain temperature and pressure conditions through the action of pressure and temperature. Multilayer presses have advantages such as compact structure, simple operation, safety and reliability, and high production efficiency. They are widely used in the manufacturing of various plastic products, rubber products, composite materials, etc., such as compressors, auto parts, building materials, furniture, daily necessities, and many other fields.

Multi-layer press This is a relatively common three-dimensional pressing equipment. Its principle is to transform the pressing material into the desired shape under certain temperature and pressure conditions through the action of pressure and temperature. Multi-layer presses have advantages such as compact structure, simple operation, safety and reliability, and high production efficiency. They are widely used in the manufacturing of various plastic products, rubber products, composite materials, etc., such as compressors, auto parts, building materials, furniture, daily necessities, and many other fields.

1. Classification of multi-layer presses According to different pressing methods, they can be divided into two types: mechanical multi-layer presses and hydraulic multi-layer presses.

2. Its composition It consists of upper and lower pressing plates, upper and lower heating plates, heating system, oil cylinder, and electrical control system.

3. It is necessary to master the pressing temperature and pressure, reasonably allocate the pressing raw materials, ensure the quality of the pressed products, and maintain the hygiene and cleanliness of the equipment.

4. During use, it is necessary to regularly check whether the hydraulic oil is sufficient, clean the upper and lower heating plates and pressing plates, check the normal working conditions of parameters such as temperature and pressure, and clean the oil stains on the surface of the heating rod.

5. Development trend: With the continuous development of science and technology, the automation, digitalization, intelligence, and energy saving and environmental protection of multi-layer presses have received widespread attention and promotion.

In short, the multi-layer press is a common three-dimensional pressing equipment suitable for manufacturing various composite materials. It has the advantages of compact structure, simple operation, safety and reliability, and high production efficiency. To ensure the normal operation of the multi-layer press, it is necessary to operate, maintain, and maintain it strictly and correctly.

Multi-layer presses are machinery and equipment widely used in the manufacturing industry. Its applications are very extensive, including solar panels, electronic components, auto parts, building materials, insulation materials, and furniture manufacturing. Multi-layer presses consolidate different types of materials together by pressing them, achieving bonding and fixation between different types of materials, improving production efficiency, and shortening manufacturing cycles.

A multi-layer press is a device that presses different types of materials together under certain pressure and temperature to bond and solidify them. The operation requires the following steps:

Adjust the pressure: Set the appropriate pressing force according to the type and thickness of different pressing materials to ensure firm bonding; adjust the temperature: Set the appropriate temperature according to the type and properties of different pressing materials to ensure that the bonding materials can be quickly solidified; place the materials: Place the materials to be pressed on the worktable of the press, ensuring that each piece is placed accurately; start the press: Start the press according to the requirements and perform pressing; after pressing, wait for the materials to cool naturally for a few minutes; integrate the materials: Use special tools to bond the pressed materials together to form a complete product.