The operating principle of a cold press

Published Time:

2022-01-21

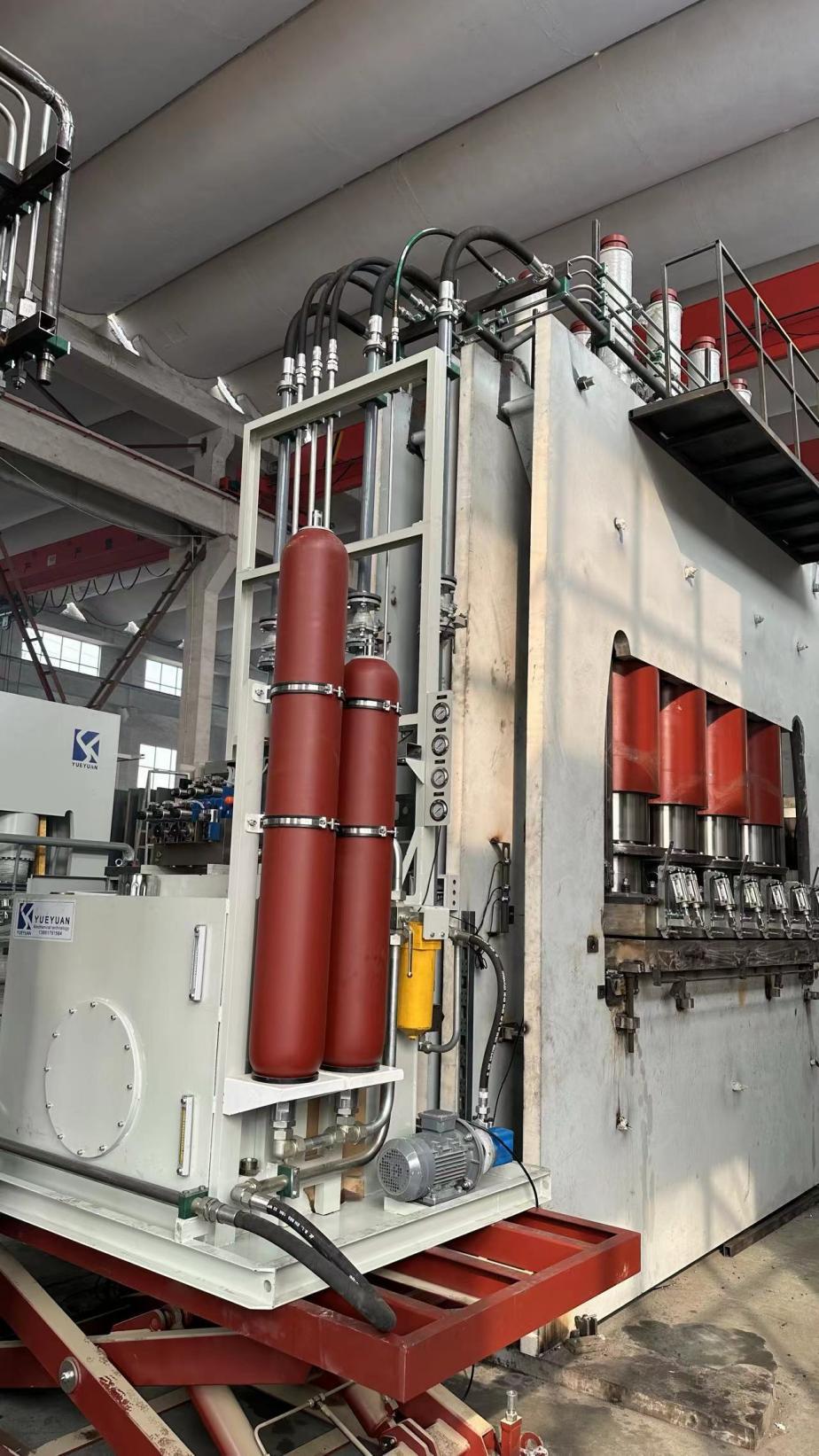

Cold presses are divided into screw cold presses and hydraulic cold presses. Screw cold presses have turbines, require long-term maintenance, and are prone to damage. Hydraulic cold presses are not prone to oil leaks, do not require frequent maintenance, and have higher work efficiency.

Cold presses are divided into screw cold presses and hydraulic cold presses. Screw cold presses have turbines, require long-term maintenance, and are prone to damage. Hydraulic cold presses are less prone to oil leaks, require less frequent maintenance, and have higher work efficiency.

Operation

The normal operation of a cold press should meet the following points: ① The hydraulic oil should be suitable for the oil quality of the cold press, generally using 45# wear-resistant hydraulic oil. ② The oil used in the cold press should be replaced once a year to ensure the normal operation of the machine. ③ Other parts should be regularly maintained. ④ Pay attention to the lighting during work, so that operators and staff can clearly see the numbers on the control box, leaving as few blind spots as possible. The cold press workshop should be clean and brightly lit. ⑤ Check the relevant operation status of the equipment every day to ensure it is in good condition. ⑥ Check for oil leakage every day and maintain it promptly. ⑦ Both parties involved in shift handover should ensure thorough handover and careful acceptance, and record the handover situation, problems, and operation status.

Shutdown

Cold press shutdown generally falls into the following categories: ① Meal break shutdown: requires a dedicated person on duty. ② Single-shift shutdown: requires the main power to be cut off when the equipment is not in operation. ③ Holiday shutdown: the main power is cut off when the equipment is not in operation. If the temperature is below 0 degrees, the accumulated water in the equipment should be drained to prevent damage to equipment components. Maintenance should also be carried out after shutdown, and the equipment should be checked for maintenance every 15 days. ④ Long-term shutdown: maintenance in a non-working state should follow the above operations to prevent damage to the equipment in a natural environment.