Definition and introduction of hot press

Published Time:

2022-01-20

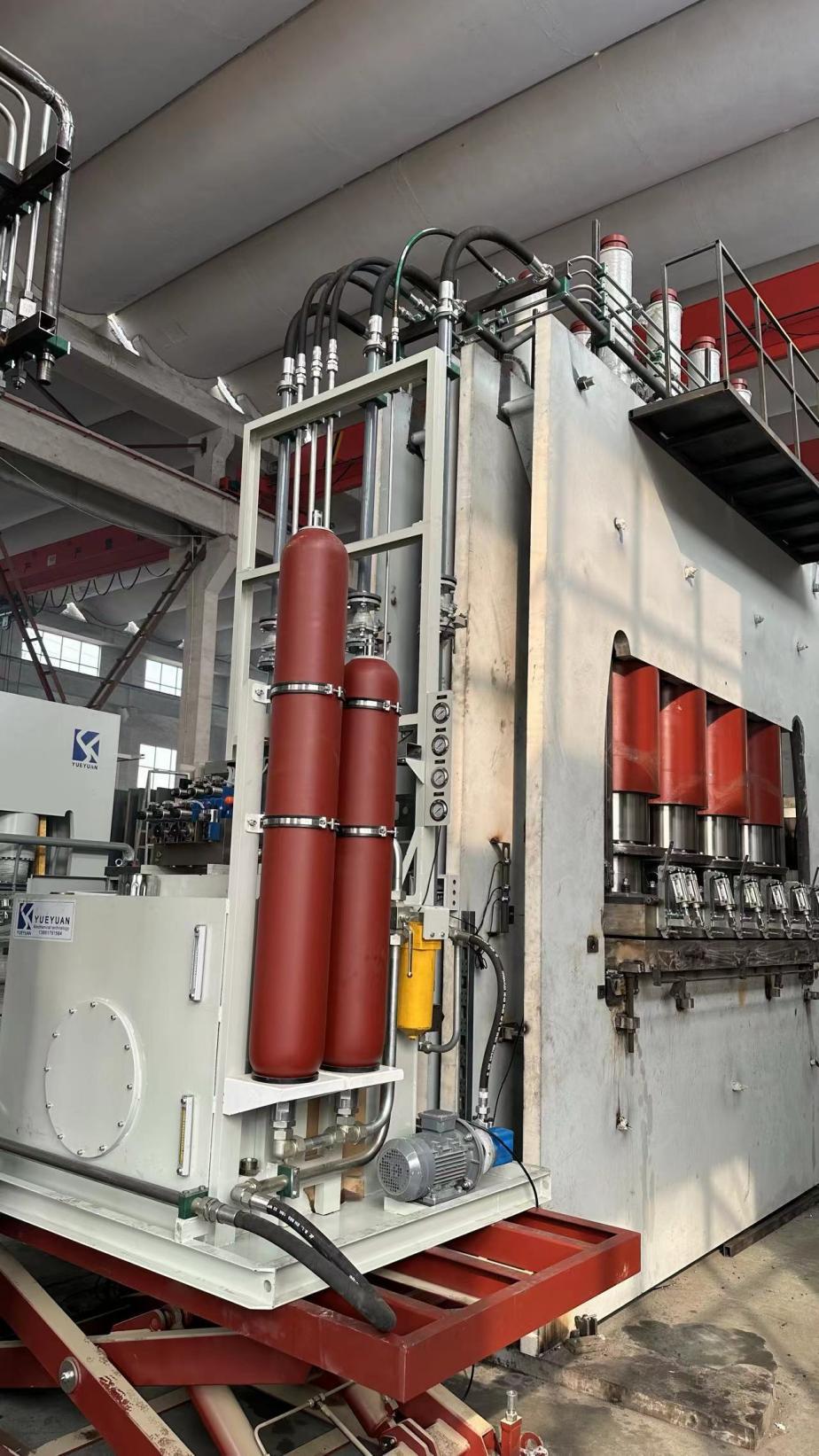

A hot press is a device that heats two pre-tinned parts with flux to a temperature sufficient to melt and flow the solder, forming a permanent electrical and mechanical connection between the parts and the solder after solidification.

A hot press machine heats two pre-tinned parts with flux to a temperature sufficient to melt and flow the solder, forming a permanent electrical and mechanical connection between the parts and the solder after solidification. The heating rate can be selected according to different products. The titanium alloy press head ensures even temperature distribution, fast heating, and a long service life. The press head adopts a horizontally adjustable design to ensure even pressure on the components. The temperature is digitally controlled for clarity and precision. It is equipped with a digital pressure gauge for preset pressure ranges.

A hot press machine is also known as a bonding machine. Depending on the medium used for hot pressing, it can be divided into solder bonding, ACF (Anisotropic Conductive Film), ACP (Anisotropic Conductive Paste), and TBF (Thermo-Bonding Film). It is suitable for connecting FPC (Flexible Printed Circuit), HSC (Zebra Paper), TAB, LCD, and PCB. Due to the miniaturization of PCB or FPC pitch in consumer electronics, traditional soldering processes can no longer meet the requirements of ultra-fine hot pressing. ACF processes have been gradually adopted by mobile phone designers.