General maintenance methods for hot press laminating machines

Published Time:

2022-01-12

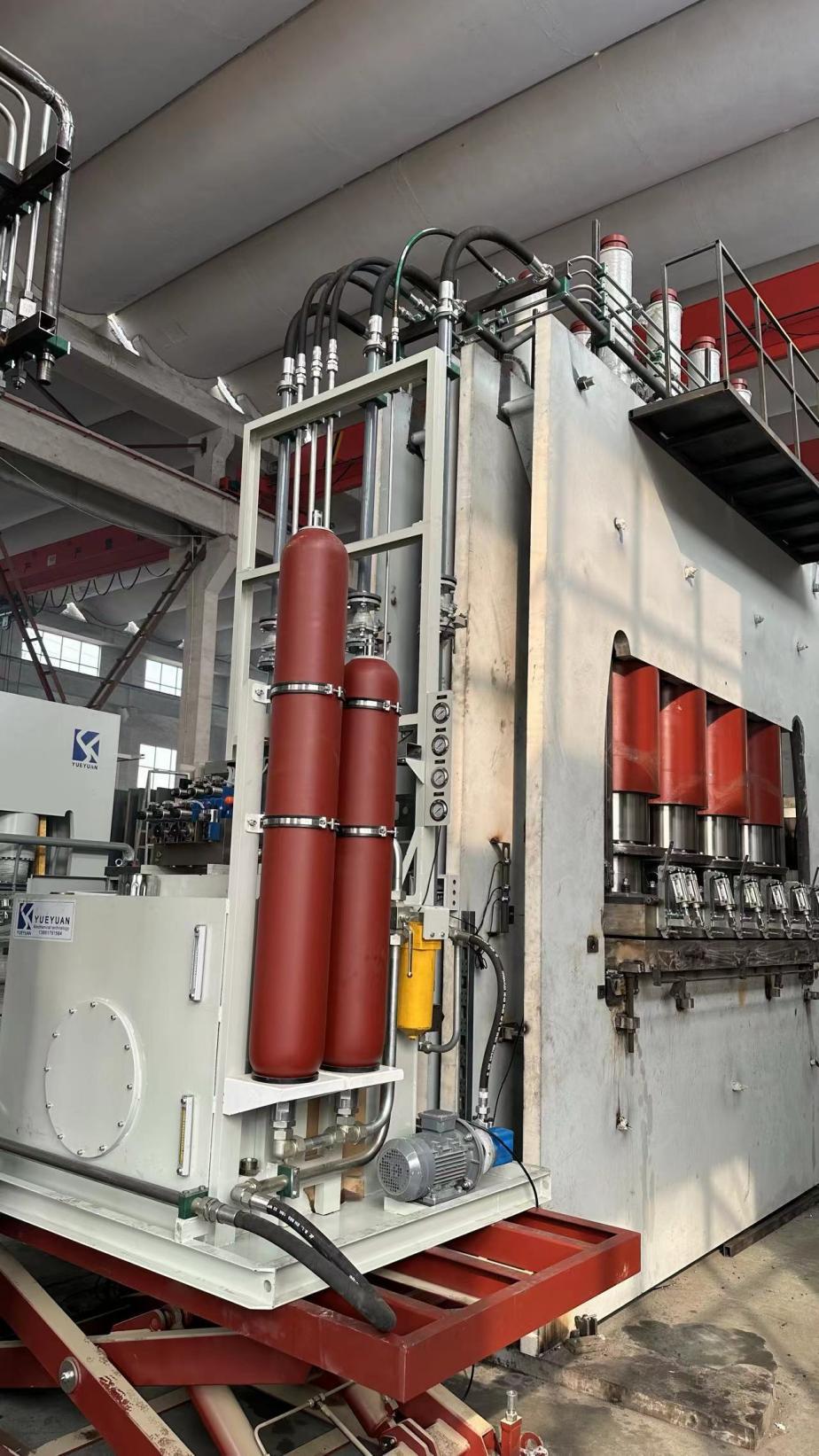

The surface hot press machine, with its easy operation and other characteristics, is widely used in wood processing, decoration, building materials and other industries. In use, attention must be paid to timely maintenance to avoid problems when using the hot press machine, especially in terms of cleaning.

Veneer hot presses, with their ease of operation and other characteristics, are widely used in the wood processing, decoration, and building materials industries. During use, attention must be paid to timely maintenance to avoid problems during the use of the hot press, especially in terms of cleaning. So, what are the general methods for the maintenance and upkeep of veneer hot presses?

1. Remove the hot press plate, use a steel brush to remove rust stains, and then use diluted hydrochloric acid (concentration 15%~20%) to thoroughly remove rust stains, revealing the metallic color of the plate.

2. Use a 5mm422 electrode for overlay welding in the corrosion area. Because unilateral overlay welding will form a sawtooth-shaped plate, it is recommended to use two-sided overlay welding so that the weld stress cancels each other out.

3. Use a double gantry planer to plane both sides of the overlay welded pressure plate, with a planing allowance of 0.5 mm.

4. If the plug weld cracks due to gas cutting, excavation is required. That is to say, after double-sided planing, each pressure plate must be individually subjected to a steam pressure test. Mark any areas where water is found. After the steam test is extinguished, use an angle grinder to create a long or round groove at the water ball weld, and then perform overlay welding.

5. Regarding the processing of PVC series materials, its linear positioning and adhesion are incomparable to negative pressure equipment, because it has high pressure, low temperature, and short film pressing time. This addresses the deformation problem of workpieces (large-area workpieces) processed by negative pressure equipment, greatly reducing the degree of workpiece deformation.